2-step rev limiters are fairly common at car meets, drag racing, and rally events. In fact, they’re even offered from factory in many production cars in the form of launch control.

As the name suggests, rev limiters are designed to work in multiple stages by holding the engine RPM at 2 or sometimes even 3 levels, depending on the configuration.

The device is commonly used in drag racing and in any scenario where off-the-line traction and optimum launch control are of great importance.

With 2-step limiters, the first stage holds the revs to properly get off the line, while the second stage (the conventional or factory rev limiter) prevents the engine from over-revving and internal damage.

In this article, we’ll discuss 2-step vs launch control in detail, and we’ll compare this technology with anti-lag.

What Is a 2-Step Launch Control? How Does It Work?

As mentioned earlier, you will usually see 2-step rev limiters on different types of race cars, particularly dragsters and rally cars.

But it’s not uncommon to see the setup on even some of the best supercars. The sole purpose of this tech is to get the best possible launch and 0-60 time out of your car.

Did you know that your engine doesn’t need to rev all the way to the redline for a perfect launch? If anything, it’ll create a lot of unnecessary wheel spin.

To avoid this, a 2-step rev limiter, a.k.a launch control, locks the revs at a point where you get the most amount of effective torque.

If it’s a turbocharged engine, launch control helps to keep the turbo in boost to reduce lag and optimize power delivery.

Because traction is key here, the 2-step device (OEM units in particular) is set up specifically for the car, factoring in the engine characteristics for a better launch. In other words, it’s set up differently for different cars.

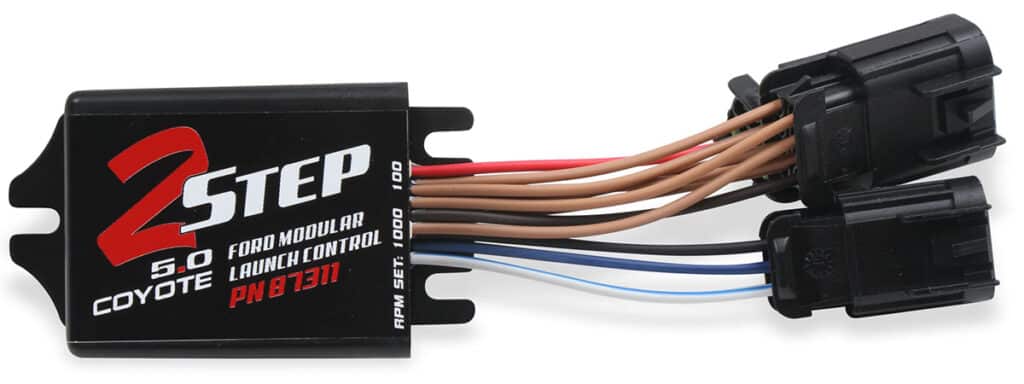

Aftermarket units, however, are a bit more generic. Interestingly, some units (both OEM and aftermarket) allow you to set the exact RPM limit, unlocking an added level of customizability.

With OEM 2-step limiters, the revs are controlled by momentarily cutting off fuel supply, and in contrast, most aftermarket units do so by cutting off the ignition.

Retarding the ignition timing is common practice when it comes to holding the engine’s RPM at a certain limit.

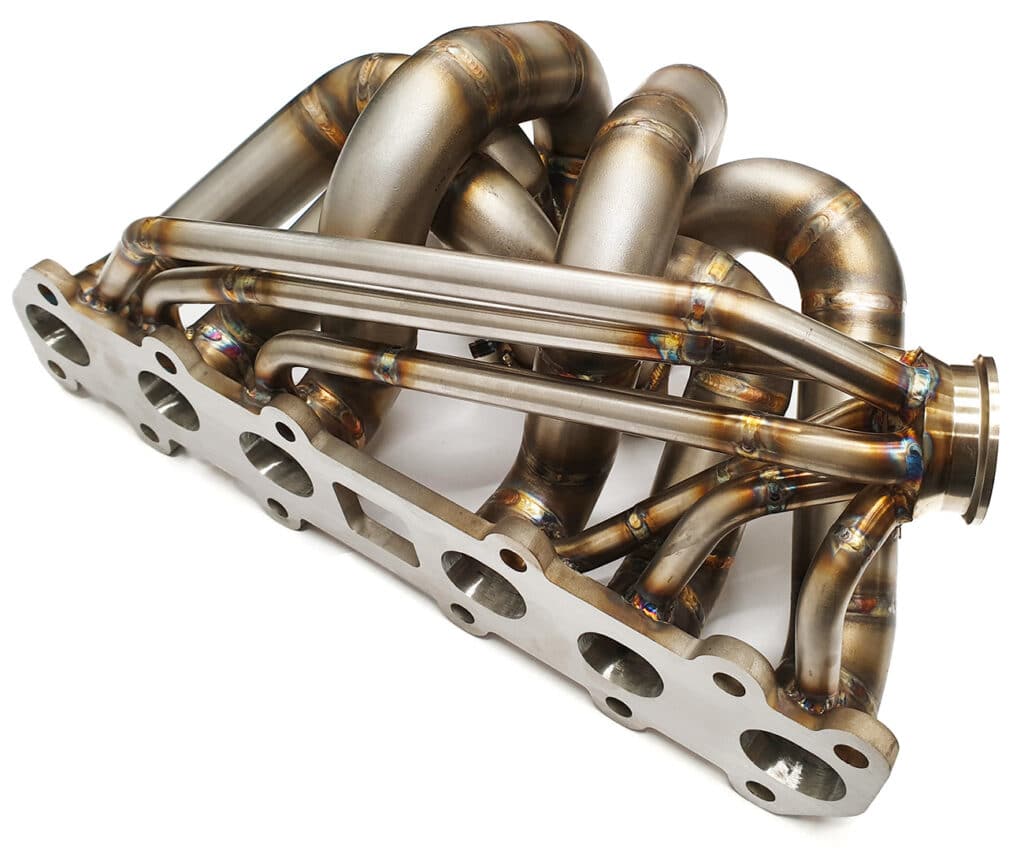

The problem here is that cutting off the ignition (or partial ignition) results in a lot of unburnt fuel entering the exhaust manifold or headers.

That’s why you hear pops and bangs out of ignition-cut 2-step systems; that’s the unburnt fuel igniting in the exhaust system. It’s a great way to make your exhaust louder.

Most OEMs prefer the fuel adjustment route, where either the fuel is cut off or a lean AF mixture is supplied to limit the revs.

2-Step vs 3-Step Launch Control

3-step launch controls are a common sight at dragstrips. To be honest, it’s not that different in operation from a 2-step unit.

The only noticeable difference is that an additional line-lock feature is programmed into the device, enabling burnouts to help warm up the tires. The rest is pretty much the same as a 2-step rev limiter.

As you can tell, a 3-step rev limiter is pretty exclusive to drag cars. You’ll find a 3-step launch control (OEM-supplied) in a Dodge Challenger or Ford Mustang, especially in models with the line-lock feature.

Several aftermarket companies are now making the device accessible to drag racing enthusiasts. Simply plug in the 3-step limiter, get the wiring done, and you’re good to go.

There are different modules that need to be wired in. By selecting the line-lock circuit (via a switch), one module can be activated during the burnout. The rest of the modules will be activated depending on the situation.

For instance, if you’re on the starting line, you can activate the second limit. When no modules are selected, the system defaults to a conventional rev limiter.

These aftermarket systems work by altering the ignition timing. However, they may require additional Timing Control and Retard Modules, which are usually sold separately.

How Is 2-Step Different From Anti-Lag?

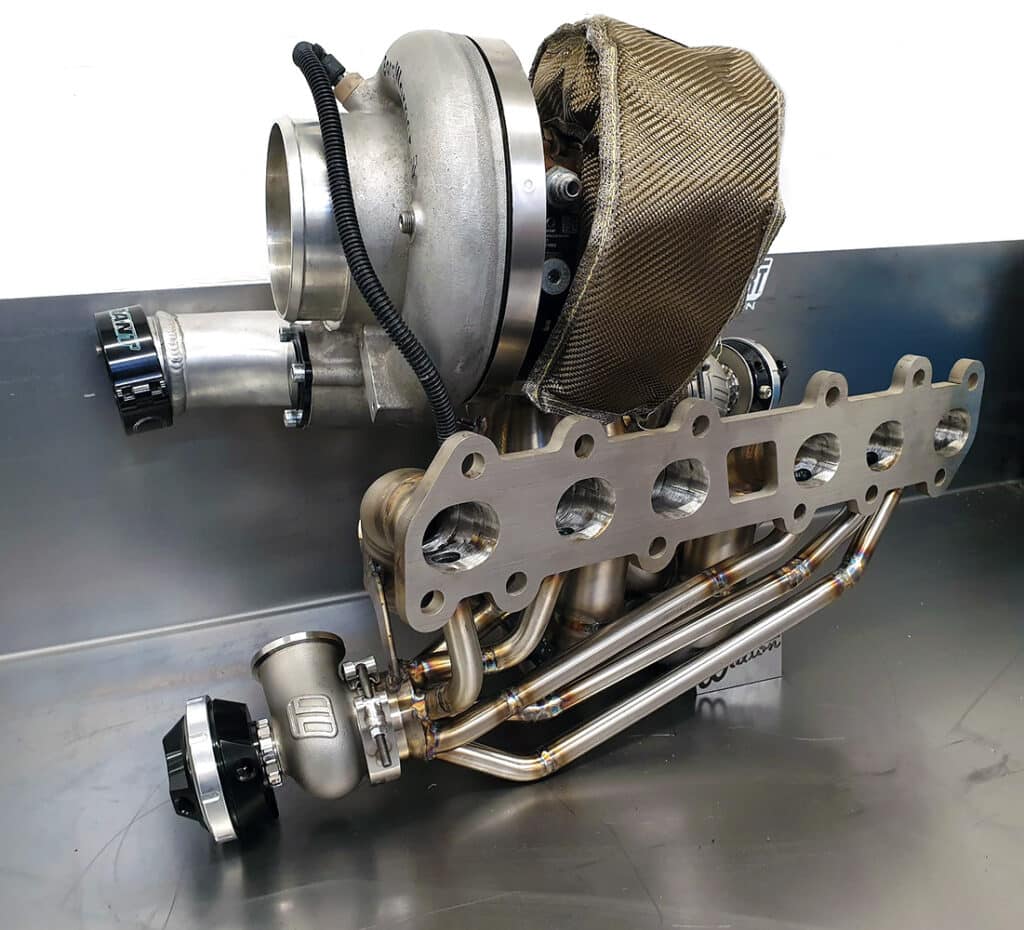

Something else that’s commonly misunderstood is anti-lag. While you may find a 2-step rev limiter in both naturally aspirated and forced induction applications, anti-lag is exclusive to turbocharged cars.

The latter is pretty common in rally racing, where you might’ve heard and seen loud pops from exhaust systems. This is done to keep the turbo spooled up in order to reduce the lag.

Anti-lag systems dump a rich AF mixture into the exhaust manifold when the engine is at zero throttle.

Because the surrounding components are hot, the mixture gets ignited inside the turbo housing, sometimes with an external air supply (secondary air injection), creating a pressure wave that keeps the turbo spooled.

This ensures that the lag is eliminated when you’re back on the throttle. Some anti-lag systems work by delaying the ignition timing and are often combined with fuel dump or secondary air injection.

This causes the combustion to happen much later, roughly at the start of the exhaust stroke. The mixture, therefore, ignites closer to the turbine, causing it to spool quicker.

Since most aftermarket 2-step units use retarded ignition timing to hold the revs, many assume the system is similar to anti-lag. While they may seem to operate in the same way, their intended use is entirely different.

2-step rev limiters are employed to get the perfect launch, whereas an anti-lag system is there to, as you might’ve guessed, reduce the turbo lag.

The excess fuel entering the exhaust manifold is what causes the pops, bangs, and flames. You may notice this in both systems, however, anti-lag puts a lot of stress on the turbo manifold and the turbine housing.

2-step, on the other hand, is relatively less taxing, but it does stress the transmission and drivetrain components, especially with frequent use.

Summing Up: Is 2-Step Bad for Your Motor?

Unlike anti-lag systems that will chew through turbos, 2-step is relatively safe for naturally aspirated motors as long as you don’t stay on it forever — 2 to 4 seconds is more than enough for a perfect launch.

Production V8 motors have been doing this for years, and many JDM cars come with 2-step from the factory, like the 4B11T equipped, turbocharged Mitsubishi Evo X.

However, if yours is an aftermarket add-on, then you’ve got to make sure that your ECU tune fully supports your engine’s optimum torque band.

Do you love or hate the sounds from 2-stepped exhaust systems? Let us know your thoughts by leaving a comment below!

If you liked this post, please share it with your friends on Reddit and Facebook, or post it on your favorite car forums. We appreciate your support!