It’s impossible to talk about Honda engines and not mention VTEC. Although the technology was introduced at the tail end of the 20th century, it has progressed through several iterations since the dawn of the millennium.

VTEC is essentially Honda’s proprietary acronym for variable valve timing and valve lift. Every car manufacturer implements this technology differently.

It may not sound special in today’s world of crazy horsepower, but it was a game-changer for Hondas from the 90s and early 2000s — the golden era of naturally aspirated, rev-happy VTEC motors.

In this article, we’ll take an in-depth look at Honda’s revolutionary VTEC technology and how it differs from the more sophisticated i-VTEC version.

What Is Variable Valve Timing?

Modern engines use variable valve timing to improve performance, emissions, and fuel economy. As you might have guessed, the technology involves altering the valve timing to tailor to both low and high RPM requirements.

In a piston engine, the camshaft is responsible for opening and closing the valves. These valves supply air and fuel to the engine, while also being a gateway for expelling spent gases.

When it comes to DOHC engines, both intake and exhaust valves are operated via separate camshafts.

As the engine cycles through intake, compression, combustion, and exhaust strokes, the cam lobes push against the followers connected to the rocker arms, which then open and close the valves at a certain time.

The cam lobe’s oval design influences how much the valves open and for how long they remain open. The timing of the opening and closing of these valves is determined by a timing chain or belt driven by the crankshaft.

To better understand variable valve timing, you’re going to want to get familiar with valve lift, duration, timing, and overlap.

- Valve timing: Measured in degrees, refers to the precise opening or closing of a valve relative to the piston’s position. It is often advanced or retarded based on the engine’s performance and efficiency demands.

- Valve duration: For how long the valve is kept open.

- Valve lift: How far the valve is opened.

- Valve overlap: The point at which both the intake and exhaust valves are open at the same time.

It’s worth mentioning that valve timing, lift, and duration under low RPM conditions are very different from those at high RPM. For instance, idling doesn’t require a lot of fuel, so valves can be closed sooner for better emissions and efficiency.

However, at high RPM, the fuel and air requirements are significantly higher, so the valves need to stay open for longer to allow more airflow. Manufacturers employ cam phasing and cam changing methods to alter valve timing and lift.

How Does VTEC Work?

VTEC stands for Valve Timing and Lift Electronic Control, which is Honda-speak for electronically controlled variable valve timing and valve lift. The technology is based on cam changing.

As mentioned earlier, the cam lobe’s design, otherwise called “cam profile”, impacts valve lift and duration. Generally, variable valve timing incorporates cams of varying profiles, and the situation is no different in VTEC.

However, it’s the way Honda has designed and implemented the system that separates it from the other automakers.

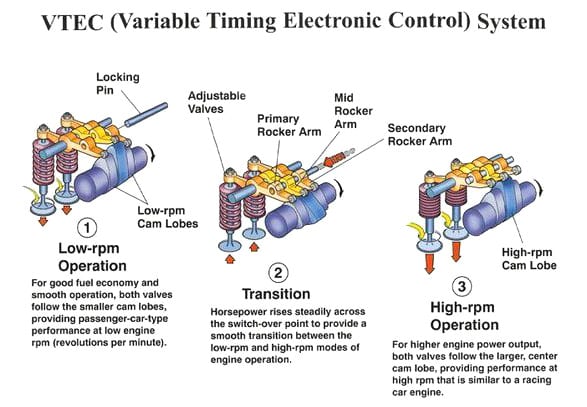

In the case of VTEC, you get a single high-lift cam sandwiched between two low-lift cams, with two different rocker arm designs. The system can be employed on the intake side, exhaust side, or both.

While the low-profile rocker arms control one valve each, the high-cam rocker (also called the central rocker arm) is responsible for controlling both valves at the same time. The central rocker sits between the two low-profile rocker arms.

However, it’s worth pointing out that the central rocker arm is not in direct contact with the valves. This raises the question of how it controls the valves.

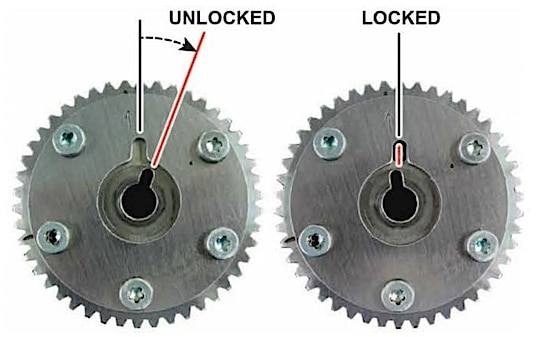

Honda designs their high and low rocker arms in a way that they lock in with each other whenever required with the help of a hydraulic piston or locking pin.

At high RPM, the oil pressure naturally increases, pushing the piston and locking the rocker arms as a result. The two outer rockers then move with the central rocker arm, driven by the high-lift cam, opening the valves indirectly.

When the RPM is low, oil pressure drops, effectively disengaging the piston and unlocking the rocker arms. So now, the two low-lift rockers operate the valves while the central rocker arm simply moves up and down without influencing anything.

i-VTEC vs VTEC

VTEC only controls timing via valve lift and duration, but i-VTEC combines VTC (Variable Timing Control) and VTEC to improve the engine’s low and mid-range torque delivery.

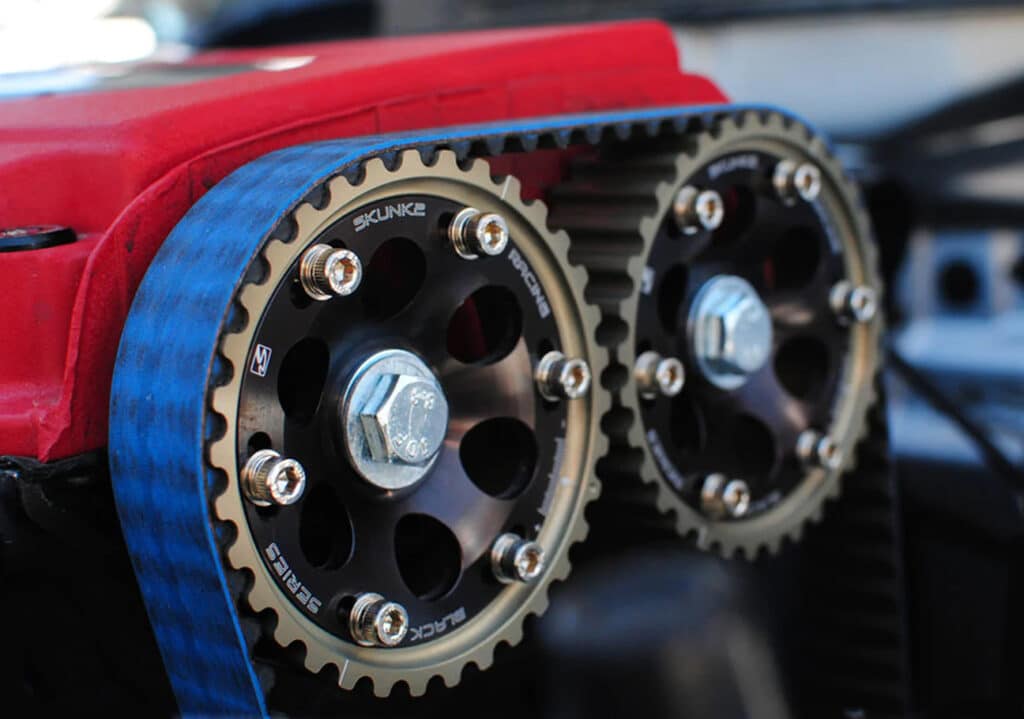

Performance-focused i-VTEC motors, specifically more advanced iterations of the K20 engine, the K20A2 and K20Z3 use VTEC on both the intake and exhaust side with VTC only on the intake side.

Economy-focused i-VTEC engines employ VTC but with VTEC only on the intake side. Some Honda engines even add VTC on the exhaust side for greater precision.

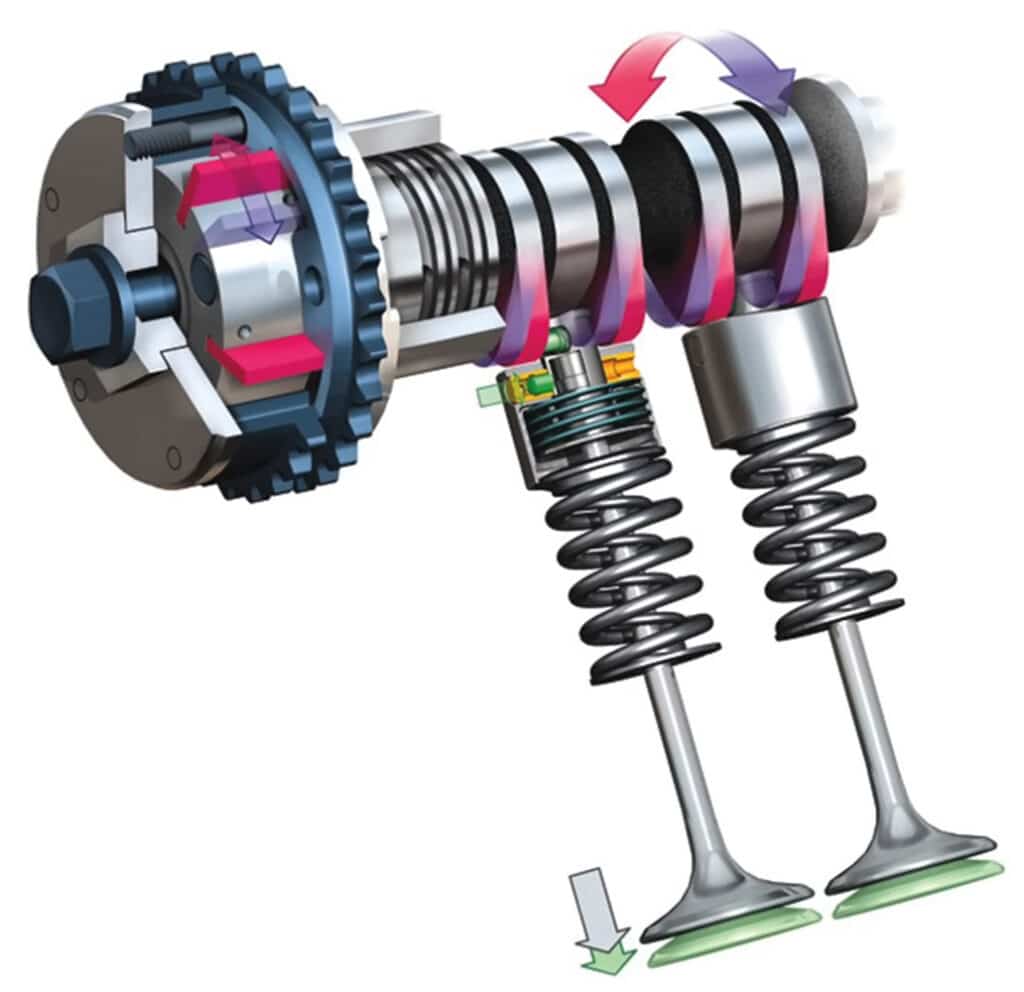

Variable timing control (VTC) is achieved through cam phasing, which involves a computer-controlled, oil-driven cam sprocket.

Depending on the configuration, this system can advance or retard the valve timing. It does this by using hydraulic pressure to rotate the camshaft relative to the crankshaft’s angle.

Various sensors are used to relay information to the ECU about engine speed and other important data, such as pistons and camshaft position.

Generally, advancing intake timing produces better power at low RPM, while retarding the overall cam timing improves power delivery at high RPM.

Honda, however, set up VTC rather uniquely. At high RPM, the intake cam is advanced so it opens sooner for better cylinder filling.

At this stage, the intake and exhaust valves are open, creating an overlap at the same time, which draws more air and fuel into the cylinder.

In low RPM situations, Honda’s VTC retards the camshaft timing to improve idling and reduce emissions. All of this will make more sense once you know how camshafts and crankshafts work.

Are VTEC and VVT the Same?

VTEC is a form of variable valve timing (VVT) that controls valve duration and lift. While all VTEC implementations, including i-VTEC and VTEC-E, fall into the VVT category, the inverse doesn’t hold true.

That is, not all VVTs are VTEC. For instance, Toyota’s VVT-i (Variable Valve Timing with Intelligence), although a form of VVT technology, is a cam phasing system that controls valve timing and not valve lift, unlike Honda’s VTEC.

The equivalent Toyota system that controls valve timing and lift is called VVTL-i (Variable Valve Timing and Lift Intelligent System), similar to Honda’s i-VTEC.

Nissan’s NEO VVL, as seen in the SR20VET engine, is another example of variable valve timing with duration and lift control. While these VVT systems rely on a battery of sensors, the most important ones are the camshaft and crankshaft position sensors.

The Main Difference Between i-VTEC and VTEC

Now that we understand how VTEC and i-VTEC work, let’s discuss the differences. The most noticeable difference is the inclusion of VTC in i-VTEC.

Although VTEC offers significant performance improvements by altering valve duration and lift, it doesn’t change camshaft timing.

Remember, engine requirements differ at low and high RPM. Having more control over the valve timing allows the engine to be further optimized for power and efficiency.

By adding VTC, Honda managed to fine-tune valve openings, effectively widening the power band for smoother power delivery. Additionally, i-VTEC enabled Honda to make the engines more efficient while reducing emissions.

Concluding Thoughts

VTEC played a significant role in boosting Honda’s reputation as an engine maker. Of course, things have changed now, with Honda moving towards turbocharging and hybridization, but that didn’t stop them from improving on VTEC.

As part of Earth Dreams Technology, VTEC eventually made its way into turbocharged Honda engines.

Unfortunately, that marked the end of Honda’s traditional VTEC charm, simply because the system is now exclusive to the exhaust side, facilitating better turbo spools and reduced lag times.

The duality and evocative nature of early VTEC motors made a significant impact on the car culture at the time. Undoubtedly, VTEC and i-VTEC engines of the early 2000s hold a special place in our hearts.

Those were some of the best Honda engines to build, specifically the B16, K20, D16Y8, K24, and D16Z6 engines.

Not only do these motors showcase excellent reliability, but they also offer impressive performance at an affordable price.

Which manufacturer’s version of variable valve timing do you like the most, and why? Let us know by leaving a comment below.

If you enjoyed reading this article, consider sharing it with your friends on Facebook and Reddit. We appreciate your support!