Modern-day engines are incredibly complex and highly reliant on electronic components. So much so that most mechanical failures in the engine can be attributed to the malfunctioning of small and seemingly insignificant electronic parts like the crankshaft position sensor.

The positives of electronic componentry in the engine are far too appealing: they’re compact and efficient, have fewer moving components, and relay information faster.

Having various sensors and control modules has improved our ability to diagnose faults. Plug in a scan tool, and the amount of information available is beyond belief.

While all that seems well and good, it’s hard to overlook the flaws; longevity is questionable, as is reliability. Replacement costs are usually high, and mending these car parts requires special tools. Not to mention, a good understanding of electronics.

In this guide, we’ll go over what a crankshaft position sensor is, its function, and its location. We’ll also discuss what happens when it malfunctions, and what you can do about it. Let’s dive right in.

What Does a Crankshaft Sensor Do?

In simple terms, a crankshaft position sensor (abbreviated as CKP sensor) is used to monitor the position or rotational speed of the crankshaft.

The sensor then relays this information to the engine management system, which accordingly alters the fuel injection, ignition timing, and other engine parameters.

Before the advent of CKP, the distributor had to be manually adjusted, which, if you don’t know, wasn’t easy and required a fair bit of patience.

As for the sensor, the information is sent as a series of repetitive electrical voltage impulses. The rotating crankshaft induces a change in the sensor’s magnetic field, creating voltage pulses.

Through the pulse synchronization from the sensor, the onboard computer determines the position and speed of the crankshaft; calculates the opening/closing of the fuel injectors and the exact moment of firing the spark plug.

CKPs are not exclusive to just gasoline engines; it’s used in both spark ignition and compression ignition engines.

Where Is the Crankshaft Position Sensor Located?

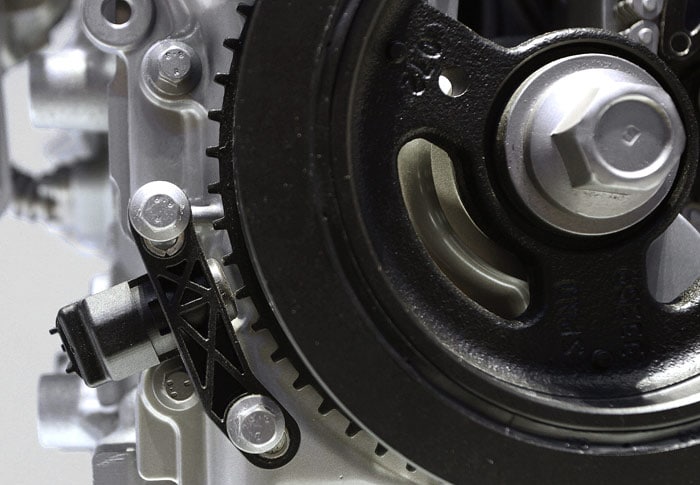

In some cars, the sensor is found close to the main pulley. In others, the sensor could be installed around the transmission bell housing or in the engine cylinder block.

The sensor will always be positioned close to the crankshaft’s reluctor ring, otherwise called a cogwheel. The ring is designed in a way that one or more teeth are missing, acting as a reference point to the crankshaft’s position.

The pulsed signal corresponds to each of the reluctor ring’s teeth. Using this information the engine control module can locate the crankshaft’s exact position and as mentioned, alter the different engine parameters.

The two commonly used types of crankshaft position sensors are Hall-effect sensors and magneto-resistive (pick-up-coil type) sensors. How do you know which one’s in your car?

An easy way to tell them apart is that the Hall-effect sensor has a three-pin connector, while the pick-up-coil type has a two-pin connector.

If that’s confusing, keep in mind that almost all modern cars use Hall-effect sensors. They offer better reliability, long life, and a non-contact operation, resulting in zero wear and tear.

Symptoms of a Bad Crankshaft Position Sensor

The first sign of CKP failure is the refusal of the engine to start when hot but will start again once the engine has cooled.

When your crankshaft sensor goes bad, your onboard computer will trip the Check Engine light. Look out for possible warning signs like:

- Erratic idling

- Hesitant cold starts

- Spontaneous increase and decrease in the engine RPMs

- Engine may stall inadvertently

- Engine will crank but won’t start

- Knock during acceleration

- Engine misfire

Now, what causes the crankshaft position sensor to go bad? One likely cause of CKP failure is exposure to extreme heat. Others are vibrations causing a wire to fracture or corrosion of the harness connector pins. Sometimes, the sensor may simply become worn out due to the car’s age and mileage.

However, modern crankshaft sensors are well-sealed and, therefore, will likely not be damaged by water, dust, or corrosion.

How to Test a Faulty Crankshaft Position Sensor?

If you found the engine to exhibit any of the above symptoms, you might have a failing CKP sensor. Scanning for trouble codes is a good way to confirm your doubts. For that, you’ll need a scan tool. Find one, hook up to the car’s OBDII port and run a quick scan.

If there’s a problem, you’ll find an error code for the crankshaft position sensor “A” Circuit, it’s pretty standard across all the brands. Companies like Mercedes, Kia, Hyundai, and Nissan use the ODBII fault code P0335 to indicate a failed CKP sensor itself.

However, it needn’t be true, a damaged reluctor ring or wiring/connector issues could also cause the CKP to act weird and trip a code.

That brings us to round two of the diagnosis. This won’t be as easy as plugging in a scan tool. You’ll have to get your hands dirty for this.

Once you locate the sensor, perform a visual inspection of the CKP and the crankshaft reluctor ring. Check the wiring harness for corrosion or any other damage. If that checks out okay, make sure the harness pins are tight and there is sufficient electrical contact.

Good so far? Now, look at the sensor and reluctor ring and see if there is enough gap between them. If it’s beyond the specified limits, the onboard computer may be receiving incorrect signals.

All this seems fine, what now? For the next bit, you’ll need an ohmmeter. That is if your CKP is the pick-up-coil type. Otherwise, for Hall-effect sensors, you’ll want a professional mechanic who knows their way around an oscilloscope to diagnose the fault.

The ohmmeter approach is pretty simple. Measure the active resistance between terminals of the CKP. If it’s within the specifications, the sensor is fine. But if the resistance is lower or higher than required, the sensor needs to be replaced.

If you’re running short on time and don’t trust your mechanical abilities all that much, it’s better to leave this to a mechanic. However, If you can manage to do it yourself, it takes away the hassle of paying someone else to do what’s essentially a preliminary diagnosis.

How Much Does a Crankshaft Sensor Cost?

Now that you’ve understood the problem, it’s time to replace the sensor. The price of a CKP sensor varies between brands.

For instance, the part costs around $60 in a Toyota Corolla, with labor around $100. However, on a lower-end Mercedes, it costs $80 for the sensor, and $150-200 as labor.

Concluding Thoughts

Replacing a faulty CKP by yourself isn’t as difficult as you’d think. Afraid you might screw it up? Don’t worry. There are several tutorials on how to replace the sensor all by yourself.

If you’re wondering how long it takes to replace a camshaft position sensor, you’d be surprised to know that it barely takes 10 minutes.

Know that it’s important to leave a proper gap between the sensor and the reluctor ring teeth. Else, it defeats the purpose of having a new sensor installed. Also, when performing repairs, you should be careful not to deform the cogwheel because this can lead to total engine failure.

Would you DIY this fix or leave it to a professional? Let us know by leaving a comment down below!