You’ve likely heard of limited slip differentials if you’ve ever looked into your driveline or competition vehicles like rally or drift cars.

But did you know that there are different types of limited slip differentials that vary drastically in terms of effectiveness and functionality?

In this guide, we’ll dig a little deeper into the mechanics of differentials and break down everything you need to know about the different kinds limited slip differential.

What Is a Differential?

Onésiphore Pecqueur invented the first differential in 1827, and it was a crucial stepping stone to the modern automobile. Differentials evenly apply power from the transmission to the wheels and compensate for when your vehicle is turning.

While turning your vehicle, the wheel closest to the turn travels a shorter distance than the outside wheel, and the differential compensates for this within itself through gears.

But while that’s how a regular, or open, differential works, a limited slip differential takes things a step further.

What Is a Limited Slip Differential?

Limited slip differentials (LSDs) work by diverting torque to the wheel with the most traction.

By delivering more power to the wheel with better traction, the vehicle gets a better grip on the road, which leads to better handling and less slipping. It’s also why many people refer to limited slip differentials as torque-sensing differentials.

Without a limited slip differential, your vehicle will divert power to the wheel with the least amount of traction. This means all it takes is one wheel to lose traction on a typical RWD or FWD vehicle for you to get stuck.

Limited slip differentials eliminate this problem — in an RWD or FWD vehicle, both tires on the drive axle need to lose traction for you to get stuck. With an AWD or 4WD vehicle, all four wheels need to lose traction for you to get stuck.

Advantages of Limited Slip Differentials

Limited slip differentials provide a slew of advantages over traditional differentials. The most significant benefit is better traction.

Open differentials get stuck whenever a single wheel loses traction, but limited slip differentials fix this problem by delivering power to the wheel that’s still getting traction.

Not only do LSDs keep you from getting stuck in inclined driving conditions, but they also improve overall handling and performance. By sending power to the wheel with the most grip, your vehicle gets more torque and power to the ground, helping you accelerate.

Furthermore, since a limited slip differential delivers most of the torque to the wheel with more traction, you’re less likely to lose traction while making sharp turns or traveling at high speeds.

By delivering power to the wheel still making solid contact with the road, it’s more likely that your vehicle will respond the way you’re expecting instead of drifting across the road.

Another benefit of an LSD in rear wheel drive cars is that it is more forgiving in a trailing throttle or lift off oversteer scenario.

Disadvantages of Limited Slip Differentials

Limited slip differentials are notorious for higher maintenance and repair costs. The clutch packs used to engage the differential wear out, and eventually lose their effectiveness.

Where open differentials are nothing more than mechanical gears, many limited slip differentials have parts that break down and wear out. If your vehicle has a limited slip differential, it’s only a matter of time before you have to replace clutch packs or perform other kinds of maintenance.

In addition to this, they can sometimes induce more understeer than you may be used to.

There’s also the question of drifting with a limited slip differential. While limited slip differentials can help with drifting by locking your wheels together under certain conditions, they don’t provide the same advantages that a vehicle with a welded differential would offer.

If you’re looking for a vehicle that performs well on the track and the road, a limited slip differential is a great choice. But if you’re looking for a drift demon, buy a welder for your home garage and weld an open differential together.

How Do Limited Slip Differentials Work?

There are tons of limited slip differentials, but they all work off the same principles. Locking the differential under different conditions keeps torque from solely going to the wheel with no traction.

There are multiple ways that a limited slip differential gets the job done, and we’ve highlighted the four most common below.

Fixed Value Limited Slip Differentials

Fixed value limited slip differentials use spring-loaded clutch assemblies to transfer torque to the wheels.

What makes a fixed value limited slip differential unique is that it has a maximum torque difference to each wheel. This maximum torque difference is a fixed value regardless of how much torque the transmission is delivering.

The most significant advantage to a system like this is its simplicity. Since the maximum difference is predetermined regardless of torque output or road conditions, you never have to worry about one wheel not receiving any power, even if it’s not getting any traction.

Torque-Sensitive Limited Slip Differentials

Torque-sensing limited slip differentials, known as Torsen LSDs use driveshaft torque to control output shaft torque and traction. The more torque at the driveshaft, the harder the clutches grip, increasing torque to the wheels.

This process increases torque to a particular wheel because as the clutches push themselves together, the drive wheels in the differential get pushed closer together too. This controls the torque delivered to each wheel.

Most torque-sensitive limited slip differentials have a preloaded clutch that keeps the clutch packs minimally applied even when there is no torque present.

Speed-Sensitive Limited Slip Differentials

Speed sensitive limited slip differentials work by comparing speeds from both output shafts and using that information to determine how much torque to apply to each wheel. Some speed-sensitive limited slip differentials ditch clutch packs and control torque output through fluid instead.

Others utilize clutch packs that are controlled by hydraulic fluid. The rotation speed of the physical output shaft controls the clutch packs, not information relayed through sensors.

The rotation of the output shaft creates pressure inside the differential that controls the torque amount delivered to each wheel.

While there are many advantages to these systems, they result in a minor loss of power compared to mechanical gears.

As the fluid heats up, viscous limited slip differentials experience fade in the transfer of power from the output shafts through the fluid, which is less efficient than connected mechanical gears.

Electronically Controlled Limited Slip Differentials

Newer vehicles have ditched mechanical linkages to control the amount of pressure applied to the clutch packs altogether and use different kinds of electronically limited slip differentials instead.

These differentials utilize electronic components to control the amount of pressure applied to the clutch packs in different situations.

This has a ton of advantages when everything is working the way that it should. The primary benefit is that the vehicle isn’t solely dependent on road conditions or torque output to prepare the differential.

The vehicle uses inputs from an external computer or controller to determine optimal torque output to the wheels before the external factors occur. This can eliminate slipping before it ever has a chance to start instead of reacting to it after the fact.

How Do LSDs Work With a 4-Wheel Drive?

True 4×4 vehicles work by locking the transfer case. These vehicles utilize a locking differential, but that doesn’t necessarily make them a limited slip differential. You need to manually activate a locking differential through the transfer case — which is where 2Hi, 4Hi, and 4Lo come into play.

This ensures that the same amount of power is delivered to each wheel regardless of road conditions or output torque.

While vehicles equipped with locking differentials can have limited slip differentials, they don’t work simultaneously. Instead, the limited slip differential will work whenever the 4WD isn’t engaged.

Different Types of Differentials

Like many other components, there are multiple types of limited slip differentials that have their own advantages and disadvantages. Below are the four most common you’ll find in modern vehicles.

Keep in mind that many manufacturers will name their limited slip differential something different, but they almost always use the same designs outlined below.

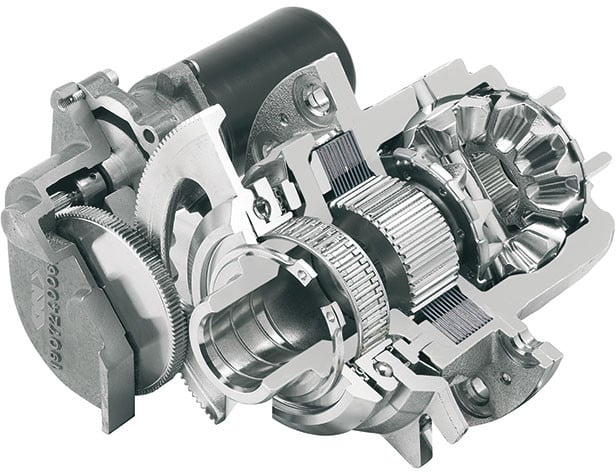

Gear Type Limited Slip Differentials

Gear type limited slip differentials come in two main varieties, Torsen LSD and helical. The most significant difference between them comes down to their patents.

However, when it comes down to how these systems work — they’re identical.

Helical Limited Slip Differentials

Helical gear limited slip differentials don’t rely on clutch packs like many other limited slip differentials. Instead, they use mechanical gears that intermittently lock when throttle conditions demand it.

They typically apply equal torque to each wheel, but this isn’t always the case depending on the individual gear ratio. The critical thing to remember is that since there isn’t any clutch pack and everything is mechanically connected, there’s no way to alter this ratio once it’s on your vehicle.

There’s one primary advantage to helical gear limited slip differentials. Since they don’t use clutches and use mechanical gears, they don’t often need maintenance. Moreover, since they don’t have clutches that wear out, you won’t experience fade over time.

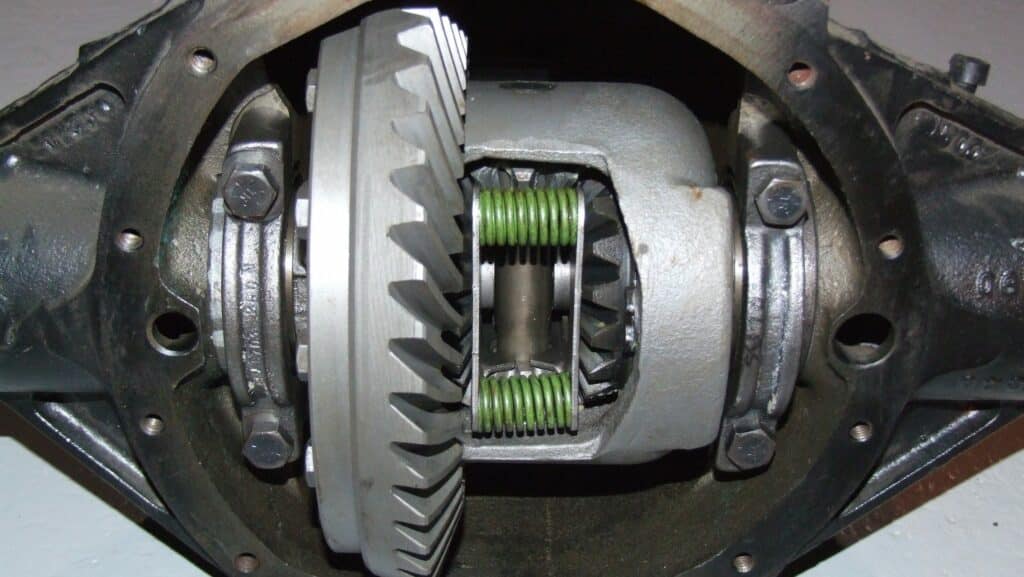

Clutch/Plate Type Limited Slip Differential

Clutch type limited slip differentials are some of the most common limited slip differentials found on vehicles today. These differentials use clutch packs to lock the differential after specific throttle or deceleration conditions.

While clutch/plate limited slip differentials are very popular, there are a few disadvantages to them. First, as the clutch wears out, you’ll experience a fade in its effectiveness. Eventually, you’ll have to replace the clutch pack, which can be expensive.

Furthermore, clutch/plate LSD’s require regular oil changes to keep everything operating smoothly. Without these oil changes, the clutch packs will wear out prematurely.

There are three different variations of plate type LSDs, and these different styles affect when the differential locks.

2-Way Differentials

2-way lock limited slip differentials lock under two different conditions. First, these differentials lock after specific throttle conditions.

Additionally, these differentials lock after specific deceleration conditions. These are the only clutch/plate type limited slip differentials that fully engage when accelerating and decelerating.

1-Way Differentials

Unlike 2-way differentials that lock during both acceleration and deceleration, 1-way differentials only lock during acceleration.

These limited slip differentials do not provide any additional traction benefits while decelerating.

1.5-Way Differentials

Both 1-way and 2-way differentials are relatively straightforward to understand. However, there is a third design of differentials known as a 1.5-way differential.

These differentials fully lock after specific throttle conditions, but they only partially lock during deceleration. This gives you the full advantage of a limited slip differential while accelerating but only a partial advantage when decelerating.

Cone Type Limited Slip Differential

A cone type limited slip differential works in the exact same way as a clutch/plate LSD. That’s because the cones themselves are just a different style clutch.

While clutch plates are flat and mesh up against each other, the clutches in a cone type diff are cone-shaped. This allows for more surface area to contact each other without widening the overall differential.

Viscous Limited Slip Differentials

Viscous limited slip differentials don’t utilize gears or clutch plates. Instead, they use fluid. As the pressure in the fluid changes, it locks and unlocks the differential. While this has several advantages, it has its downsides too.

The most significant disadvantages are that these differentials experience a considerable performance fade over time and they provide unequal amounts of torque split.

However, the perks of a viscous limited slip differential include a gentle engagement compared to clutch or gear type limited slip differentials. Furthermore, these sealed differentials don’t require any maintenance.

Once they do wear out, typically after around 60,000 miles, you have to replace the entire differential to regain the torque and traction benefits.

All viscous limited slip differentials are 1-way as they only lock during acceleration.

How to Maintain Your Limited Slip Differential

For gear and clutch/plate type limited slip differentials, you’ll need to change your oil according to the manufacturer’s maintenance schedule. Clutch plate differentials require more oil changes than gear differentials, but the maintenance is relatively easy for both.

Simply remove the drain plug and let the old differential oil drain out before removing the fill plug and adding the correct fluid.

Differentials require a thick oil, at least 80 weight. Most differentials use 90 weight oil. If you’re looking for a little extra service life, there are special additives that keep everything functioning correctly.

Keep in mind if you have a viscous limited slip differential, no additional maintenance is possible or needed.

Repairing vs Replacing Your Limited Slip Differential

If you’re experiencing problems with your limited slip differential, you’re probably wondering if you’ll need to replace the entire differential or whether or not you’ll be able to repair it.

The good news is that unless you have a viscous limited slip differential, the answer is almost always to repair it.

When to Replace a Differential

There are only two conditions where you’ll have to replace the differential every time. The first is when you have a viscous differential. Viscous differentials are entirely non-repairable no matter the problem.

The second issue is if you have a cracked differential housing. You can, however, weld small cracks shut. So it’s typically only a significant problem if the cracks are extremely large.

Things You Can Repair

Outside of the more complicated electrical units, limited slip differentials are highly serviceable. For most problems, all you need is a decent tool set and thorough service.

If your differential is experiencing any leaks from the rear cover, this is one of the most affordable repairs. Even better, all you typically need is:

- The part

- A flat head screwdriver

- A ½” ratchet set.

If you’re experiencing problems with either the clutch packs or gears inside your differential, you can repair this too. While you might need to replace the individual gears or the clutch packs, this is still far cheaper than replacing the entire housing.

Start by removing both wheels on the axle at the same time and remove the output shafts too. Then remove the rear cover to reach all the gears. From there it’s going to come down to the specific kind of differential that is in your car.

Better Performance Guaranteed

Limited slip differentials have been one of the most groundbreaking car components since their inception.

Instead of losing the ability to move as soon as a single wheel gets stuck, limited slip differentials have found a way to deliver that torque to the wheel that still has traction to keep you moving.

While limited slip differentials are growing in popularity and becoming increasingly common, there are still plenty of vehicles with an open differential out there.

What’s your take on LSD vs open diff? Let us know which differential you’re currently using in the comments below!