Crawling over difficult rock sections in your Tacoma is a lot of fun, until you bust open your door sills and rocker panels. To avoid that, you need to install rock sliders.

But rock sliders aren’t cheap; so to ensure that you’re getting your money’s worth and buying the right product for your needs, you need to evaluate the various available options based on their design and construction.

In this article, we’ll discuss some of the features and advantages of rock sliders, and we’ll conclude with some of the best options that you can buy.

What Are Rock Sliders?

Rocker panels are load-bearing components that need to be kept intact. This is especially important for those who frequently hit the trails and take off-roading seriously.

Rock sliders or rock rails reinforce the structural integrity of your truck by protecting your rocker panels. They also prevent accidental damage which would otherwise be a very expensive fix.

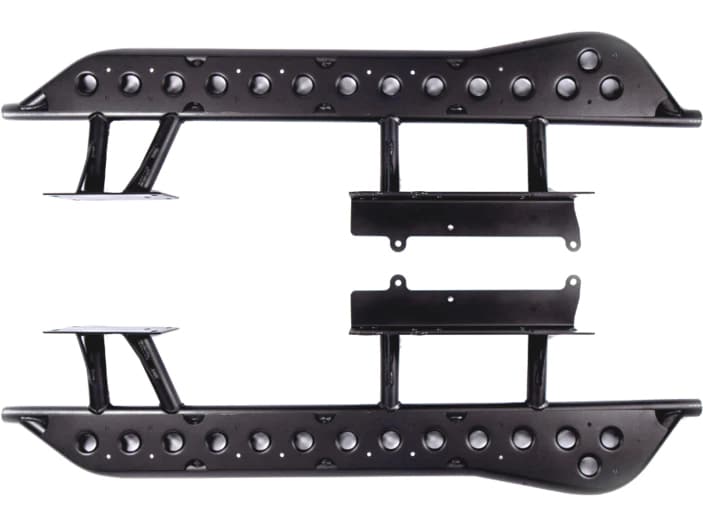

These are square or round (or both) sections of steel that run along the side of your truck.

You mount them to your rig’s frame and in turn they support the entire weight of your truck, all while protecting it against damage from constant grinding or sliding over obstacles.

Because they need to support a ton of weight, rock sliders usually are made of heavy-duty thick steel.

You will still find some aluminum rock sliders, but steel is by far the only sensible choice if you’re expecting to take lots of hits on your rocker panels, or frequently crawl over tricky terrain with stuff like tree stumps and boulders.

Steel adds both weight and price to your sliders, to the point that you can usually tell a quality steel pair from regular nerf bars based on the cost alone.

Note that different people opt to armor their vehicle with a pair of rock sliders for different needs. That’s why most reputable manufacturers don’t stock mass-produced sliders because they’re usually made to order.

Why Your Tacoma Needs Rock Sliders

Before deciding if rock rails are the right armor for your Tacoma, it helps to understand their basic functions; along with their construction and design characteristics.

Below we’ve discussed some of the reasons why you should consider installing rock sliders:

- Protection: They help you slide off rocks and stumps without having to worry about damaging your truck.

- Kickout: Tacoma rock sliders with a kickout will push your rig away from obstacles and avert direct contact.

- Pivot point: You can use the kickout as a pivot point in tight turns.

- Recovery point: Should you ever need a rollover recovery, your rock sliders can act as a stabilizing point by easily handling the weight of your rig.

- Steps: Rock sliders with steps make it easier for you to reach your Tacoma roof racks, camper shell, and windshields.

What Should You Consider When Choosing Rock Sliders?

Now that you know the most common reasons why you should install a pair of rock sliders on your Toyota Tacoma, let’s take a closer look at some of the design related options that you have available to you.

The first factor to consider is the construction because that’s what determines the strength and weight bearing capacity of your sliders.

Strength: DOM vs HREW

The most appropriate metal for constructing rock rails is steel. When it comes to the type of steel used, you have two options:

- Hot Rolled Electric Welded (HREW) steel tube

- Drawn Over Mandrel (DOM) steel tube

These are not necessarily types of steel, rather they indicate the process the steel goes through that determines its strength.

HREW

HREW is a more affordable option, albeit less popular and offered by fewer manufacturers.

It’s good for light vehicles and for those who are just getting started with off-road driving. However, it’s more susceptible to denting and bending.

DOM

DOM is superior when compared to HREW as it provides approximately 20% more strength, which is why most reputable shops use it as their standard material.

While it resists dents and scratches better, it is also more expensive as it goes through additional steps during the manufacturing process.

Aluminum is also offered by some shops, but it’s a good sign that the product you’re viewing isn’t a proper rock slider.

As opposed to steel and its derivatives, aluminum is a lot softer and it easily flexes upon impact, in which case the tubing itself will damage your rock panels regardless. All in all, we do not recommend aluminum sliders.

Design: Kickout, Fill Plates, Angle, Length

Choosing the right design is a great way to get more functionality out of your rock sliders.

Below we’ve discussed some of the options you have available to you such as kickouts, step plates, angle, and more.

Kickout

A kickout is a bulge in the tubing that pushes or kicks the truck out of the way when going around a tight obstacle (such as boulders, rocks, or trees).

Even if you don’t intend to abuse your sliders to that extent, it’s okay to opt for a kickout if you like the way it looks.

Kickouts also provide an added area to step on if your rock sliders don’t come with fill plates, and they are perfect for protecting long wheelbase vehicles such as Tacomas.

Step Plates

Step plates, fill plates, or top plating all refer to the same thing — a full or partial covering for the space between the tubes. It’s made of sheet metal and increases the surface area of your rock sliders.

If you want to make it easier for yourself and your passengers to get in and out of your truck, we highly recommend you opt to have your sliders covered with step plates.

These can be used as a jump-off point if you end up parking in muddy spots. Many Tacoma owners appreciate the added accessibility that stepped rock sliders provide.

Most shops offer various textures for fill plates, but we recommend a dimple die texture over a sleek sheet because it provides more traction in wet and muddy conditions.

Angle

The standard angle for most sliders is between 10° and 25°. The lower the angle of your sliders, the better they function as a step, whereas the higher the angle, the more flush they are with your rocker panels.

Frequent off-roaders benefit from 15° and above, which also happens to be the industry standard. If you decide to go with angled sliders, make sure they stick out far enough by reviewing the photos.

Length

Be wary of getting the right sized sliders for your rig. The size you get depends on which generation Tacoma you have, and also whether it is a Double-Cab Short Bed (DCSB), Access-Cab Long Bed (ACLB), or Double-Cab Long Bed (DCLB) vehicle.

As long as you know which model your rig is, picking the size is a matter of two clicks between the three options in most shops and not a point of concern.

Note that the longer the sliders are, the more expensive they will be because they need more material.

Coating: Bare, Powder Coating, DIY

Coating your rock sliders protects them from rust, deterioration from being exposed to the elements, and some minor dings.

Some coating options can cost up to $300. But know that no matter how expensive it is, it won’t stand the test of time forever and touch-ups are inevitable.

- Bare: The cheapest option that all manufacturers offer at no cost. Some will offer to sand your rock sliders in case you want to DIY a paint job later.

- Paint: A paint job is either offered by the manufacturer or can be DIYed with whatever paints you have available.

- Powder coat: Powder coating is the most expensive and sleek-looking option offered by most manufacturers. It is not ideal for serious crawling due to chipping.

- DIY: The sky is the limit is you want to take things into your own hands. While many owners paint their rock sliders, another DIY project with more lasting results is using a bed liner.

Mounting: Weld-On vs Bolt-On

When it comes to installing rock sliders, you can either choose to weld them on to your frame, or you can bolt them on.

Both methods have their own pros and cons which we’ve discussed below so you can make the right choice.

Bolt-On

Bolt-on rock sliders are easier to install and remove in your own garage, more affordable, and less likely to ruin your warranty depending on how much drilling they require. The best bolt-on designs don’t require other modifications to the frame.

There is always a chance you’ll end up having to drill your rig’s body. This will negatively affect the resale value of your truck.

If you opt to drill the frame of your rig, it will require a careful paint job and regular maintenance, especially under dirty and damp conditions.

To keep the drilled area from rusting, we also recommend that you consider either drain holes or regular blowouts.

Weld-On

Weld-on rock sliders are much harder to DIY and require professional welding skills — an added expense. That’s unless you’re good at welding and have access to a welder for home use.

They are also a more permanent option and will most definitely affect both manufacturer warranty and resale value. That said, for off-road dedicated rigs, weld-on sliders offer better protection and can take on more abuse.

If you are going to weld your sliders all by yourself, you’ll have to order them bare because any coating will have to be applied after the sliders have been welded to your rig’s frame.

The Best Rock Sliders for 1st, 2nd, and 3rd Generation Tacoma

If you’ve done your fair share of research on rock sliders, or if you’re familiar with several Tacoma owners in the off-road community, you’ve probably come across some popular names such as Relentless, Marshall Fab, Pelfreybilt, and Mobtown.

Unfortunately, most of these have either been discontinued or are inactive. The only way to buy these is by scouring the used market or checking with retailers who might still have them in stock.

Rock sliders are typically made to order. The lead times provided are not set in stone; depending on how busy the manufacturer is and how many modifications you require, the time required for your rock sliders to be ready will fluctuate.

The following is an updated list of some of the most well-known brands and some new names in the off-road aftermarket segment for 1st, 2nd, and 3rd gen Tacoma rock sliders.

SOS Concepts

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on

Kickout: Optional

Coating: Black powder coating

Fill plates: Optional

Angle: 15°

Lead time: 3 to 4 months

SOS Concepts opened shop in September 2013 in South Carolina. They had humble beginnings in a garage with a rented welder and a grinder, but after 9 years they’ve gone through many expansions and their designs have won them loyal customers.

They offer bolt-on 2nd gen Tacoma sliders for DCSB and access cabs, along with options for Double Cab Long Bed (4×4 only) cars. Their DOM sliders come with either round tube (1.75″x.120″) or square tube (2×2.125″) options.

These sliders can take a beating with no problem, and their new designs come with drain holes to prevent rust. As far as customer service is concerned, they’re always one phone call or email away.

RCI Metalworks

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM, HREW

Mounting: Bolt-on

Kickout: Standard

Coating: Bare metal, satin black powder coating

Fill plates: Optional top tread plates

Angle: 20° (Standard), 5°

Lead time: 1 to 2 months

Aftermarket truck and SUV accessories are RCI Metalworks’ specialty. Based in Loveland, Colorado, they’re loved for their comparatively short lead time, reasonable shipping costs, and customer service.

All of their rock sliders are coated with an epoxy primer for more longevity. You can pick sliders in two sizes, one for Double Cab Short Bed and Access Cab rigs, and another for Double Cab Long Bed ones.

Bay Area Metal Fabrication

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Optional for 2005 to 2021 trucks

Kickout: Standard

Coating: Optional powder coat

Fill plates: Optional dimpled fill plates

Angle: 20° (standard), 10°, 0°

Lead time: 2 to 4 months

Bay Area Metal Fabrication (BAMF) was born in Jerry Lee’s home garage in 2011 out of his passion for quality Toyota off-road products, and has grown to be one of the most respected shops in the market.

Like most other manufacturers on this list, BAMF builds their sliders to order, so their lead time varies, but they do offer batch builds for larger orders.

Their sliders come in two sizes; the 80″ sliders fit the Double Cab Short Bed, and both Extra and Access Cabs, while the 96″ sliders fit the Double Cab Long Bed rigs.

While their bolt on design requires no further modifications to the frame, please note that for 1st gen Tacomas and some 2010 models, light modifications might be required.

Their sleek square tube design continues to be a fan favorite, and you get to choose any other modifications as options on their website.

CBI Off-Road

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM, HREW

Mounting: Optional (weld-on available for limited models)

Kickout: Optional

Coating: Bare metal, black powder coating

Fill plates: Optional reverse dimpled dies

Angle: 15° (standard)

Lead time: Unspecified

With roots that go back to 1999, CBI Offroad is a reputable brand based in Idaho with a passion for craftsmanship and technology combined.

Their rock sliders can be purchased in 3 different design options:

- Overland

- Trail

- Classic

The difference between the three is in angle and kickout, with similar add-ons and options.

The Overland series sliders have a 0° angle and are perfect as steps, while the Trail series are not only angled but also boast a kickout.

Note that fill plates are not an option in the Trail series. The Classic series has all the qualities of the Trail series without the standard kickout.

Trail-Gear

Models: 1st gen, 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on and weld-on

Kickout: No kickout

Coating: Bare

Fill plates: No fill plates

Angle: 0°

Lead time: Unspecified

Even though Trail-Gear opened shop in 2005, they’ve acquired three older and newer shops over the years due to their rousing success. Today they are known as Trail-Gear Family Companies and all specialize in quality off-road products.

Trail Gear has two series of rock sliders available for Extra Cab, Double Cab and PreRunner Tacomas. All their sliders are 78″ and they fit rigs built between 1995 and 2015.

These sliders can be either welded or bolted on (using 1/2″ bolts that are not included in the kit), but we recommend you take the weld-on route as they are not the easiest to line up when bolting.

All-Pro Off-Road

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on

Kickout: Standard

Coating: Black powder coating, bare

Fill plates: Standard (Apex Series), none (HD Series)

Angle: Standard upward angle

Lead time: Unspecified

All-Pro Off-Road was established back in 1996, making them one of the first few reputed manufacturers in the off-road aftermarket.

Together with Low Range Off-Road and Wheeler’s Off-Road they make up the three companies acquired by Trail Gear in the past few years. All-Pro rock sliders come in two series, the HD and the APEX rock sliders.

Both series use a 1.75”x.120 DOM tubing and both come at an “upward angle,” while the APEX series also features a 120” dimple died steel plate. Kickouts are native to both designs and you cannot opt them out.

All-Pro makes sliders for ACLB, DCSB, and DCLB rigs, but the latter comes at an added cost.

C4 Fabrication

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on

Kickout: Optional

Coating: Bare

Fill plates: Optional (with C4 branding)

Angle: 0° (for fill plates), 25° (standard)

Lead time: 2 weeks

With over 15 years of experience, C4 Fabrication has been a staple in the Toyota community and is a reputable name when it comes to high-end off-road armor.

C4 Fab has some of the cleanest sliders on the market with a signature look. Their Tacoma DCSB sliders weigh 75 lbs each, while their DCLB sliders are 90 lbs. These also fit ACLB rigs.

Unlike most other shops, C4 Fab does not offer powder coating and ships their sliders bare. This is because not all buyers have powder coated bumpers, which can result in rust but would look uneven with a coat job done by another shop.

Note that their sliders are fully bolt-on and they do not have an option for weld-on models.

BudBuilt

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on

Kickout: Optional

Coating: Bare, sanded bare, textured black

Fill plates: None, diamond plates, dimple die up, dimple die down

Angle: 20º

Lead time: 2 months

Bud Rosenberger’s products are known for their top-notch quality, superior strength, and low-profile design.

They offer plenty of options when it comes to plating and coating your sliders. BudBuilt is the only manufacturer on this list that offers both bare and sanded metal rock sliders, so you can customize your build to your liking.

Their rock solid 2″x.120 tube is mounted on a 3/8″ thick foundation, which provides excellent resistance to dents over rough terrain, and is built to fit ACSB, DCSB, and DCLB rigs.

Cali Raised

Compatibility: 2nd gen, 3rd gen 2016+

Construction: DOM

Mounting: Bolt-on, weld-on (for select models only)

Kickout: Optional

Coating: Bare, powder coat, bedliner

Fill plates: Optional, bare filler plate, powder coat, bed liner filler plate

Angle: 25°, 0° (Step Edition)

Lead time: 1 to 2 months

Cali Raised has been a known name within the off-road gear industry for a while now, but the bulk of their reputation comes from their one-of-a-kind lighting mounts, kits and bars.

In recent years they have launched their range of rock sliders. They offer the most variety in coating options for fillers and the sliders, which means you can mix and match the options as you please.

While they aren’t the only manufacturers that don’t upcharge for features such as kickouts, it’s certainly a bonus.

Their sliders come in two Trail and Step editions, both of which are made using 1.75″ DOM tubing and are available for all models (DCLB, DCSB, and AC).

Demello Off-Road

Models: 1st gen, 2nd gen, 3rd gen 2016+

Material: DOM

Mounting: Bolt-on, weld-on

Kickout: Available in some models (ACLB, DSCB)

Coating: Bare, powder coat

Fill plates: Available in some models

Angle: 10°

Lead time: 1 week to 3 months

Based out of Riverside, CA, Demello Off-Road is a reputable brand with nearly 20 years of experience, and they make some of the best Tacoma rock sliders that you can buy.

Apart from the basic round and square tube designs, they offer a Hybrid series which is a combination of both tubing shapes.

Their Hybrid X-Wing sliders feature box reinforcements at the front and the rear for added protection, while their Stealth sliders add the benefit of a kickout to the Hybrid design.

All of their sliders are made from the industry standard 1.75″x.120″ DOM. They only offer kickout for ACLB and DCSB models, while their non-kickout designs also come for DCLB rigs.

Victory4x4

Construction: 1st gen, 2nd gen, 3rd gen 2016+

Compatibility: A500 Steel, optional aluminum outer skin

Mounting: Bolt-on

Kickout: Not available

Coating: Bare, powder coat

Fill plates: Standard

Angle: 10°

Lead time: Minimum 1 month

Victory 4×4 has deep roots in the off-road industry. As the sister company of JcrOffroad — a brand that’s been making Jeep-specific off-road armor for over 15 years — they sure know a thing or two about quality.

They make great budget-friendly Tacoma rock sliders that are easy to install. They also have a unique semi-plated design, barring their fully plated Blitz models. The semi-plated ones are called Strike.

These sliders are angled as standard and you can opt to have them powder coated or you can order them bare.

Brute Force Fabrications

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: Unspecified

Mounting: Weld-on

Kickout: Standard

Coating: Bare

Fill plates: Optional

Angle: 10°

Lead time: Minimum 4 to 5 months

Brute Force Fabrications make high-quality bumpers and rock sliders for Toyota Tacoma owners in universally liked designs.

Their rock sliders come in the standard 2″x2″x.120 measurements and are weld-on only. As a result, they do not offer powder coating services as weld-on sliders need to be installed before they can be coated. Currently they only offer kickout models.

White Knuckle Off-Road

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: DOM, HREW

Mounting: Bolt-on

Kickout: Standard

Coating: Bare, optional powder coat

Fill plates: Optional dimpled top plates

Angle: 15° (Standard), 0°

Lead time: 2 to 4 months

Based in California, White Knuckle Offroad offers a range of handmade aftermarket products not just for the Toyota Tacoma but for many other trucks and SUVs.

For the 1st gen Tacoma, they have designs for both Extra Cab Standard Bed and Double Cab Short Bed models.

Their prices are reasonable, and they offer niche options such as rear-only dimpled plates for 1st gen Tacomas. Quality-wise, their sliders have a proven record of top-notch strength and customer satisfaction.

Shrockworks

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: Unspecified

Mounting: Bolt-on (drilling required)

Kickout: Not available

Coating: Bare, optional powder coat (plain or textured)

Fill plates: Optional dimpled fill plates

Angle: 30° (standard, no plates), 0° (step plates)

Lead time: 2 to 4 months

Based in Houston, Texas, Shrockworks takes pride in offering the best strength-to-weight ratio when it comes to rock sliders.

While they don’t specify what metal they utilize, they do mention that their tubing is a hybrid of 2″ square tubing and 1.75″ round tubing.

You get to pick between two-tube support or three-tube support for added strength. They also offer products for Extra Cab and Crew Cab for 1st gen Tacomas, and more for the newer models.

4xinnovations

Compatibility: 1st gen, 2nd gen, 3rd gen 2016+

Construction: DOM, HREW

Mounting: Weld-On

Kickout: Standard

Coating: Bare

Fill plates: Step plate with TRD logo, full-length step plate with TRD logo

Angle: Depends on welding

Lead time: Minimum 1 month

With many years of experience, 4xinnovations have evolved through meticulously taking into account customer needs and designing quality products that meet them.

4xinnovations make some of the cheapest 1st gen Tacoma rock sliders. They make these for both Extended and Double Cab rigs.

You get to choose the strength of the steel, but their best option is their 1.75″x.120 DOM steel.

A 2″ kickout is standard for all their designs. Where you have the most flexibility with their sliders is in their fill plates, as their list of options is unmatched.

Our Top Picks

And that concludes our list of the best Toyota Tacoma rock sliders. You simply can’t go wrong with the manufacturers mentioned in this article.

They’re highly regarded by Tacoma owners, and we wholeheartedly recommend them. If you’re lucky, you can join group buys and discounts by keeping tabs on them.

If any of the sliders mentioned on this list catch your fancy, we recommend contacting the manufacturer ASAP as they’re built to order and many of the popular ones require a 4-month wait.

One important thing to remember before modifying your truck is to keep your insurance company informed about the modifications you plan on installing. Check out our Tacoma insurance guide for more information.

Best all-rounder: BAMF

BAMF is the one shop no one can go wrong with. They offer just the right amount of customizations along with quality designs loved by generations of customers.

Their products cover all three generations, and they also provide many other types of armor for different trucks, making them a one-stop-shop for all your off-road needs.

For 1st gen Tacomas: 4xinnovations

4xinnovations is one of the most reputable shops on this highly competitive list. They offer both HREW and DOM steel which gives you extra flexibility in both the strength of your sliders and your budget.

The most varied designs: Demello Off-Road

Demello Off-Road features a variety of different rock slider designs to choose from. Their products are known for their quality, but they also stand out by giving your rig an edge that most other designs can’t match.

Most Customizable: Cali Raised

Cali Raised lets you make your own decisions. No amount of customization seems enough with rock sliders, and if getting a pair custom made isn’t an option, getting to pick your kickout, fill plates, and coatings is the next best thing.

Most of their options are the same across models, and when in doubt, their friendly customer service is always available.

What made you want to consider installing rock sliders? Let us know by leaving a comment below! If you want to know more about maintaining your truck, check out our Tacoma oil change guide.

If this article helps you in any way, do consider sharing it with your friends on Facebook or Reddit. We appreciate your support!