Traction is just as important on the trails as it is on the track — the more you have, the better your chances of getting out of tricky situations.

Off-road performance is dictated by many different factors, such as engine power, suspension setup, ground clearance, breakover angle, and weight distribution. But perhaps the most important determinant is your differential.

You’ve probably noticed how much easier it is for some of your overlanding buddies to overcome a 3-wheeling scenario without their trucks doing the peg leg dance.

It’s probably because they have a locking differential or some type of limited slip differential at the very least.

If you’re on the fence about installing an E-locker or air locker in your truck, then you’re in luck, because in this article, we’ll go over the advantages and disadvantages of the two systems and figure out which is better.

Differentials 101: The Basics

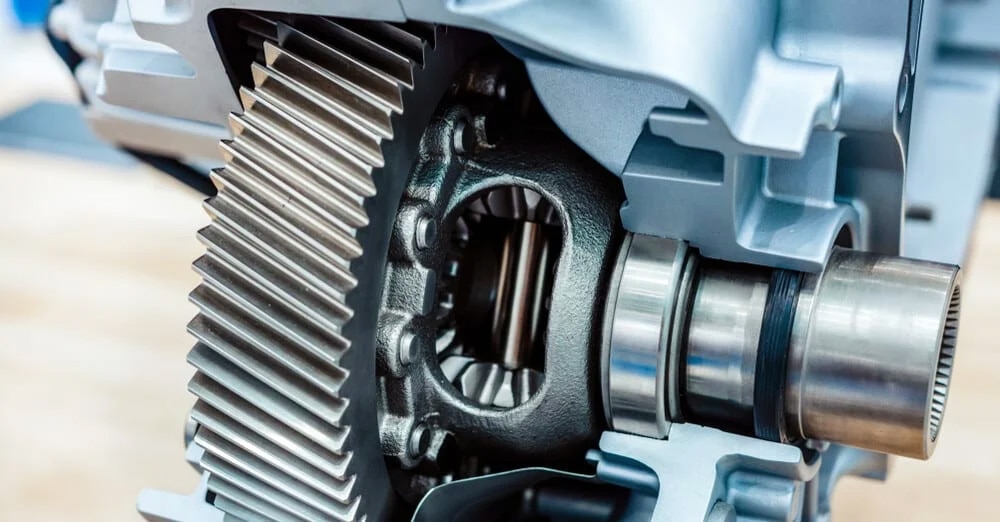

We all know power is transmitted to the wheels via a gearbox and a differential. But how exactly does a differential work in a car?

A differential allows the outer drive wheel to rotate faster than the inner drive wheel when executing a turn. The idea is to increase the speed of one wheel by decreasing the speed of the other.

In essence, a differential transfers the engine’s power to the wheels while still allowing them to rotate at different speeds whenever required.

FWD cars have a differential that sits alongside the transmission inside a housing, while RWD cars have it at the rear connected by a driveshaft.

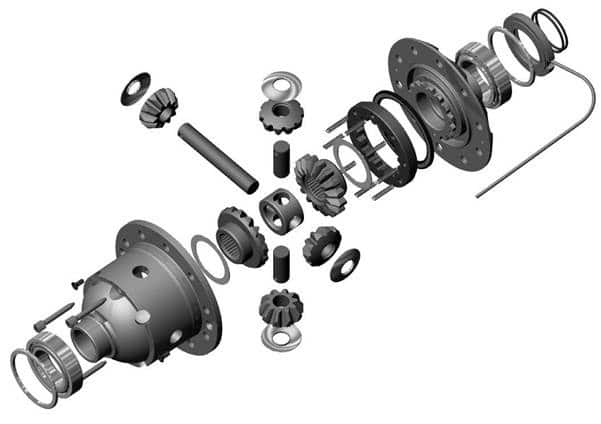

The outer wheel is rotated farther and faster than the inner wheel via an assortment of gears inside the differential assembly. A differential consists of one input (the drive shaft) and two outputs connected to the drive wheels.

The gears inside the differential ensure the average rotational speed of the two half shafts remains equal to the speed of the input driveshaft.

Depending on the application, various types of differentials are used in cars and trucks alike. Some of these include open differential, locking differential, torque vectoring differential, and the ever-popular limited-slip differential.

LSDs are non-negotiable when it comes to building drift cars. That said, it is possible to use a home welder and weld the open diff, but be warned that doing this will make the car prone to snap oversteer.

What Is A Locking Differential?

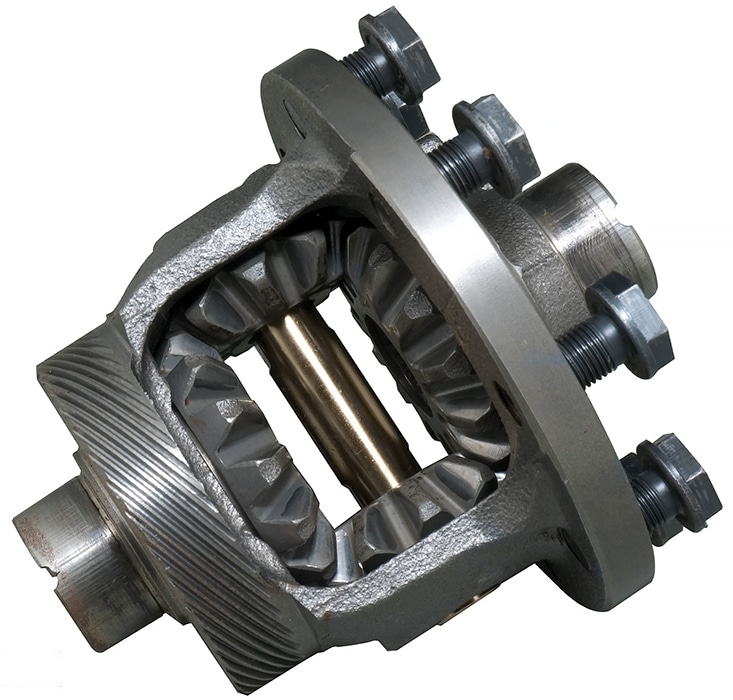

Before understanding locking differential, it’ll help to first understand how an open diff works. An open differential is a simple diff designed so that most of the engine’s power is directed to the wheel with the least amount of traction.

As you can imagine, this setup is ideal for any two-wheel-drive runabout. But it won’t be of much use on a 4×4.

Consider a scenario where one drive wheel is on the ground while the other is in the air. If it were an open differential, the engine power would simply go to the latter since it has the least amount of traction.

However, you’d still be stuck. This is where a locking differential comes in.

A locking differential can lock the two wheels on an axle, enabling both to have power at all times. In other words, a locking diff offers better traction by sending equal power to both the drive wheels.

But that’s not all, it can even send 100 percent of the power to one wheel, provided it’s the one with traction.

So from our previous example, the wheel without traction, i.e., the one in the air, won’t receive any power, while the wheel that’s stuck in the ground will get all the power. In other words, more grip. Ergo, a helping hand.

Of course, the setup is not ideal when you’re cornering — you don’t want both wheels rotating at the same speed.

However, the beauty of the design is that, during turns, a locking diff will act like an open differential, helping you execute corners effectively.

In conditions where traction is important, the differential will start locking up, sending equal power to both wheels or one wheel, depending on the situation.

There are three types of locking differentials. These include automatic, spools, and driver-selectable locking differentials. The latter can be further divided into lever/cable-operated differentials, e-lockers, and air lockers.

Electric Lockers vs Air Lockers

Before we discuss the differences, let’s understand what air lockers and electronic lockers are. An air locker locks the differential gears using compressed air supplied by an onboard compressor.

Otherwise called a pneumatic locker, the system uses air to push against a seal that drives the internal clutch gear, which then locks the internal spider and side gears.

This allows full differential lock, enabling better off-road performance.

On the other hand, an E-locker or electronic locker locks the differential gears via an electronic switch.

Both air lockers and E-lockers have the same goal of locking the differential. It’s just that, in an electronic locker, solenoids and electromagnets engage the side gears instead of compressed air.

In the case of air lockers, the switch inside the cabin initiates the compressor, which sends the compressed air via air lines to the differential. The collars inside the assembly will keep the gears locked until the air pressure is let off.

Since air lockers are positive locking, they can be switched on at any speed, with almost instant engagement.

Although you may technically activate the system at any vehicle speed, it is essential for the wheels to be rotating equally, i.e., without any speed differential. Failing to do so causes “crash locking,” which can damage or prematurely wear the internal gears.

As for E-lockers, the engagement is achieved through roller cams operated via a switch on the dashboard. This, however, requires the differential assembly to rotate a bit before locking.

It’s advised to keep the truck under a certain speed (between 0 and 20 mph, depending on the make) while engaging an E-locker.

Also, the system may not be as instantaneous as the air locker, as some rotation is required for the locking mechanism to engage.

Front Diff Locker vs Rear Diff Locker: Which Is Best?

The general consensus is to have a locking diff at the rear. In normal use cases, the vehicle’s weight transfer is such that most of the load is focused at the rear.

That’s why a rear-locking diff makes more sense. Especially if you intend to use your 4×4 on the road, with towing, hauling, and the occasional light off-roading.

You may have seen front and rear locking diffs on high-end vehicles like Range Rovers and G-Wagons, indicating their superior off-road credentials.

The choice really comes down to your preference. If you’ve dedicated a truck for epic rock-crawling expeditions, then we recommend diff locks on both axles. Otherwise, a rear locker will suffice.

Are Air Lockers Good?

Absolutely. There is nothing wrong with using air lockers for locking your differential. That said, there are a few drawbacks inherent to the system.

Firstly, it’s complex, with more moving parts and more points of failure. Plus, having seals that can wear over time is not exactly maintenance-friendly, especially since they can leak and lose air pressure.

Although having an air locker may seem like a reliability concern over the long run, it really isn’t that big of a deal. The internals of an air locker tend to be more robust, which explains its use in motorsports and professional off-roading.

Also, the engagement is instant. No waiting around or any sort of minimum speeds to adhere to.

In fact, air lockers could be your ideal choice, especially if you’ve already installed an air compressor for inflating the tires. By that, we mean an onboard compressor, not a shop air compressor.

Benefits Of Electronic Diff Lockers

The most significant advantage of an E-locker is the simplicity of its design. The roller cams separate when the E-lockers are engaged, forcing down heavy pins into the side gears, therefore locking the differential.

Unlike an air locker, the inner workings are relatively less complex, allowing the system to work off the vehicle’s 12-volt supply without needing an additional compressor.

This opens the door for potentially less maintenance concerns. As a result, most OEMs prefer E-lockers over air lockers on their 4x4s.

Next comes cost and installation. An E-locker is significantly cheaper and easier to set up than an air locker. That’s not to say it’s plug-and-play. You still need to spend on labor, which can amount to a sizable sum.

That said, the system is not without flaws. The delay in engagement and the “speed limit” can seem like a deal breaker to some. At the end of the day, it all boils down to money and how serious you are with your off-roading hobby.

Air Lockers vs E-Lockers: Which One’s Better?

So, should you choose air-lockers or go the electronic route? If you want to push the boundaries without a hint of hesitation, air lockers are the right choice for you.

Air lockers are more robust and instantaneous. E-lockers and their delayed engagement may seem undesirable to some off-road enthusiasts.

But it’s worth noting that air lockers don’t come cheap. It’s gonna set you back a hefty sum — north of $5,000 if you’re doing both axles. For the vast majority, however, an E-locker would do just fine. It’s relatively cheap to source and install.

Plus, the delay is something you can live with. It’s just a few seconds, which, in the grand scheme of things, is a small price to pay. Also, an E-locker is relatively reliable, with fewer parts to go wrong.

That said, an electric malfunction can trip the system. So it’s not entirely worry-free, shall we say.

What’s your stance on the E-locker vs air locker debate? Let us know by leaving a comment below. If you found this article informative, share it with a friend! We appreciate your support!