When it comes to gearboxes, there’s always the question of whether to use straight cut gears or not.

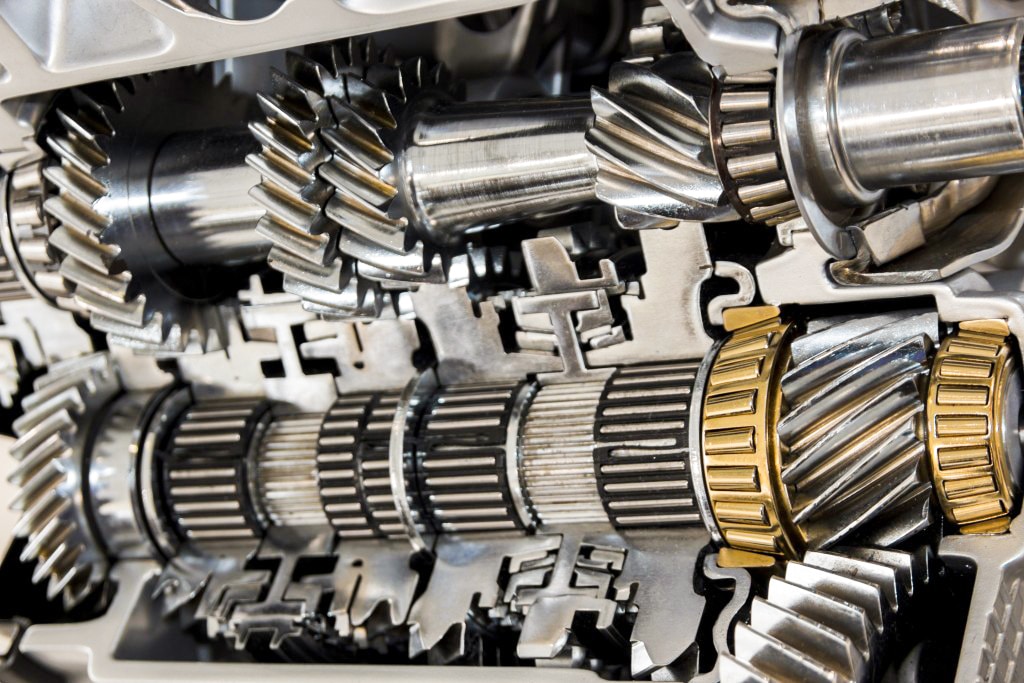

Most stock cars, whether they’re daily drivers or high-end exotic cars, feature helical gears in their transmission systems, and nobody seems to complain about them. So what’s the big deal with straight cut gears?

To know that, you’re going to want to understand what helical gears are, and how they’re different from straight cut gears.

Additionally, it’ll help to compare the pros and cons of each gear design to ascertain the right choice for any given application.

Both setups have their strengths and weaknesses, but there is a reason why passenger cars prefer helical gears and racecars side with straight cuts.

In this article, we’ll take a closer look at two of the most common gear types and understand why one’s preferred over the other.

What Are Straight Cut Gears?

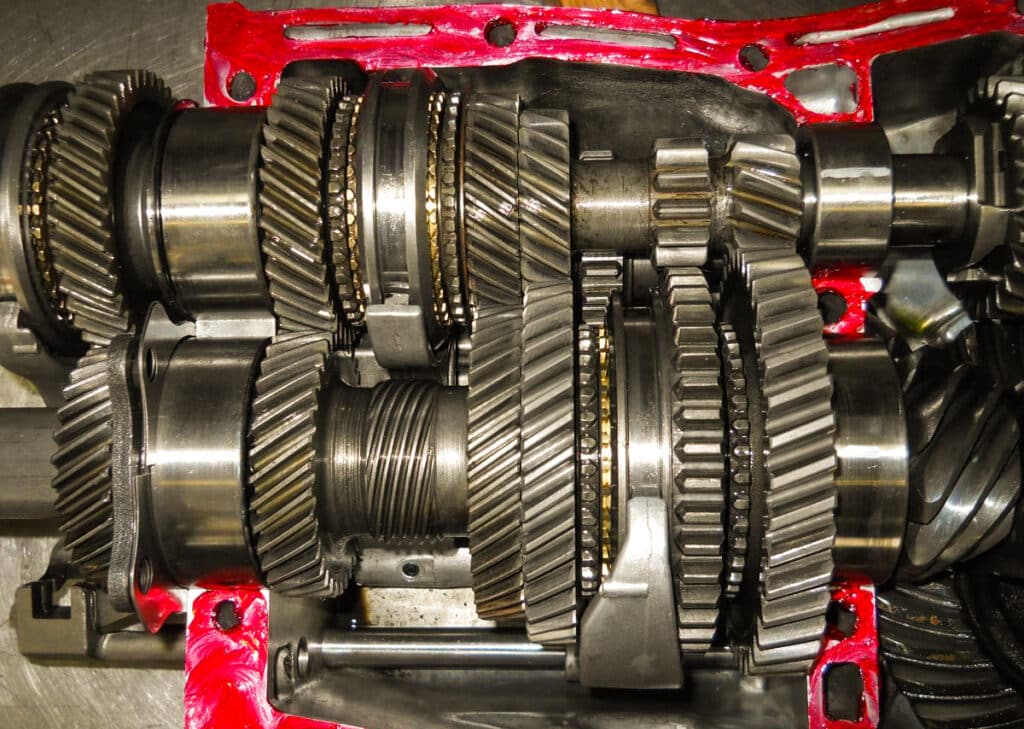

Straight cut gears or spur gears, as the name suggests, have straight cut gear teeth that are parallel to the axis of rotation.

In other words, straight cut gear systems are designed in a way that the teeth align with the gear’s mounting shaft.

It’s important to note that it is not the teeth themselves that are straight-sided but the leading edge that runs parallel to the shaft’s axis.

A notable highlight of the straight cut system is that almost no axial thrust force is created when the gears mesh together. This significantly reduces the gearbox complexities relative to a helical design.

Moreover, straight cut gearboxes are lighter owing to the lack of countermeasures to tackle the additional loads.

The inherent disadvantage of the system is the noise generated. A distinct whining sound is common, which becomes noticeably loud, especially at high RPM.

Needless to say, this might not necessarily be a disadvantage, especially if noises such as turbo flutter and supercharger whine are music to your ears, or if you like to make your exhaust louder.

Pros and Cons Of Straight Cut Gears

Although it may seem advantageous to use a straight cut gear system, it is not without its flaws. So let’s weigh the pros and cons.

Pros

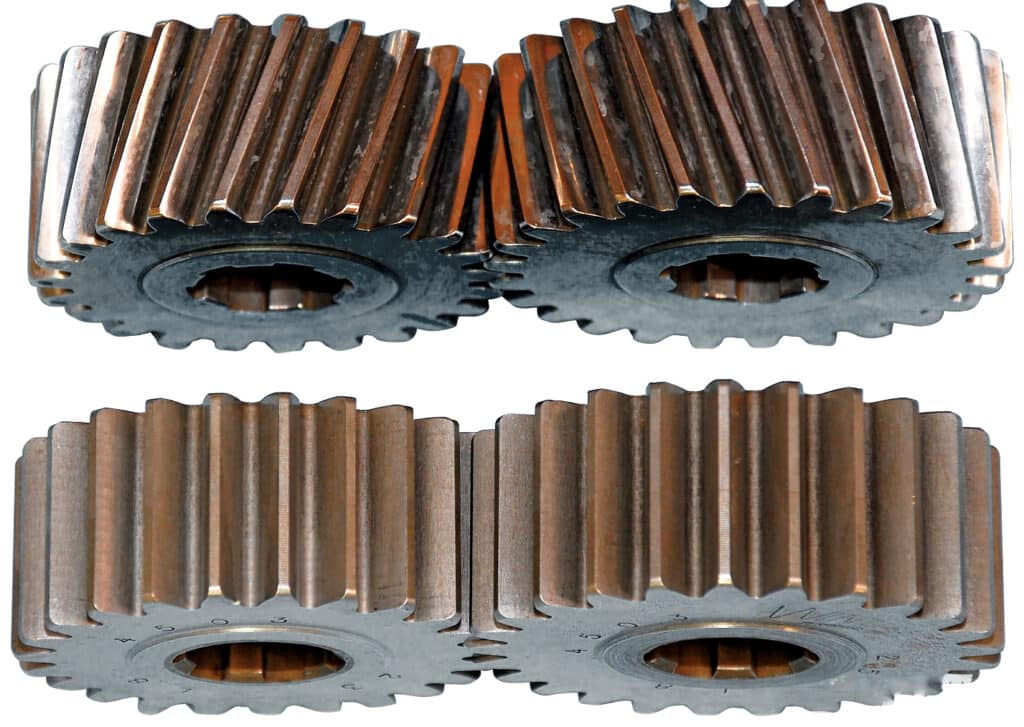

- A spur gear design is simpler to construct via hobbing.

- A straight cut system is less complex, which reduces manufacturing costs.

- Easier to assemble, owing to a simpler design.

- Straight cut gears improve efficiency by reducing drivetrain losses. Ergo, more usable power.

- Suitable for high rpm applications.

- The lack of thrust loads helps minimize the gearbox housing’s weight and size.

Cons

- As mentioned earlier, they are noisy.

- Not the smoothest gear changes; the gears often slam into each other.

- Transmitting heavy loads can cause issues due to spur gears having relatively low load-bearing surface area.

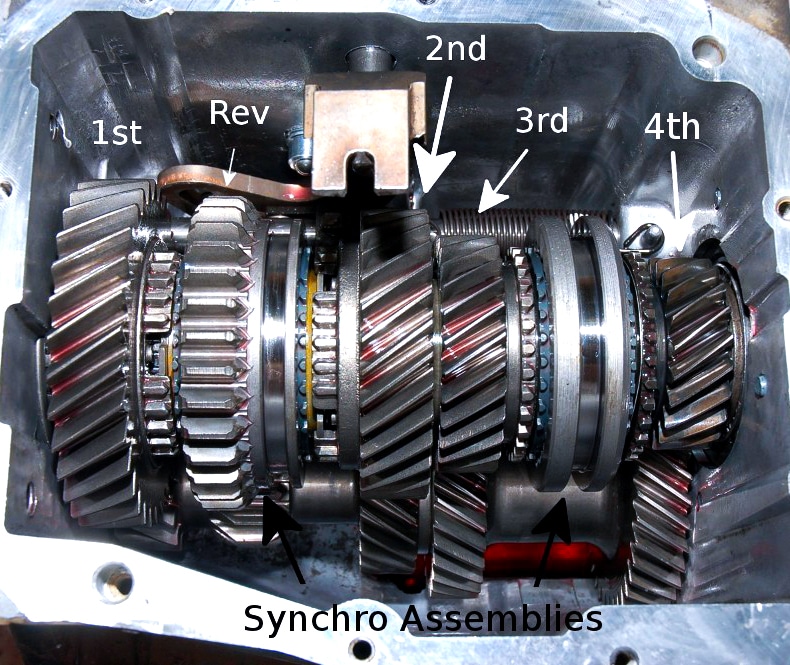

What Are Helical Gears?

Helical gears have teeth that cut at an angle relative to the face of the gear. Unlike a spur or straight cut mechanism, the teeth don’t run parallel to the axis of rotation but rather form a helix.

The angle, otherwise called the helix angle, is the measurement between the face of the teeth and the gear axis.

It can range from 15° to 30°, depending on the gear’s direction of rotation. The easiest way to picture a helical gear is to compare it with the threads of a screw.

The gears are designed such that when they engage, the contact is gradual, starting at one end of the tooth and spreading along the helical surface as they rotate.

This makes them quieter than a straight cut mechanism, eliminating the whine as a result.

Unlike spur gears, helical gears can transfer energy in both parallel and perpendicular axes. You just have to adjust the rotation angle by 90°.

The downside, however, is the axial thrust load. Since the gears rotate helically, a thrust load is generated along the gear axis when they engage.

That’s why you’ll find thrust bearings in a helical gearbox to mitigate the axial loads. The greater the helix angle and the power carried by the gear, the greater the thrust load.

Helical Gear Advantages and Disadvantages

Helical gears have several advantages over straight cut systems. However, they’re not without their fair share of drawbacks.

Pros

- Significant noise reduction, owing to the helical motion and gradual contact of the gears.

- Relative to spur gears, helical gears have more teeth meshing, which makes for a great load-bearing surface area.

- Can be employed to transmit heavy loads, as helical gears distribute the applied forces more efficiently.

- Smooth gear changes.

- Suitable for daily use and road applications.

Cons

- Expensive to machine versus spur gears.

- Adds weight and size to the internals to combat the thrust loads.

- More points of failure in contrast to straight cut systems.

- Axial loads diminish the output efficiency of the transmission.

- Increased drivetrain losses due to heat and friction.

Helical vs Straight Cut Gears: Applications

You’ll find helical gears in all road car transmissions. Straight cut gearboxes, on the other hand, are almost exclusively reserved for racing applications.

That said, road-legal hypercars like the Aston Martin Valkyrie and CLK GTR have straight cut gears, noticeable by their characteristic whine.

For anyone wondering whether or not straight gears are street legal, it’s worth pointing out that there are no laws restricting the level of sound emanating from the transmission.

Surprisingly, you’ll find spur gears even in normal cars. Ever wondered why your car whines when in reverse? Most cars have reverse gears that feature a straight cut design.

This is usually done as a cost-cutting measure. Moreover, you’re not always in reverse, and the speeds are relatively low, so the whine isn’t as intrusive as it would be in a racecar.

When it comes to racing, it simply boils down to the axial thrust loads. As mentioned, thrust load is proportional to the power a gear carries.

Since these cars have high horsepower, the gearbox (if helical) should have stronger components to endure the thrust loads at such power levels. This complicates the gearbox design and makes it substantially heavy.

The lack of axial loads, fewer failure points, and low size and weight are why different types of race cars use straight cut gears.

Not to mention the reduced drivetrain losses. Passenger cars prefer the helical gear mechanism, at least for forward gears, as they operate smoothly and silently.

The size and weight penalty is a relatively small compromise compared to the added practicality.

Final Thoughts

In the automotive realm, helical gears are most preferred, especially in passenger cars and even in some enthusiast-focused, fun daily driver cars.

That’s not to say straight cut gears are less desirable. It’s not uncommon to see aftermarket builds featuring straight cut gears; these tend to be road cars built for intense track use.

For gearheads who are willing to put up with the foibles, a straight cut system is the most efficient setup to have.

But for the vast majority of people, smoother shifts and livability take precedence over a noisy, albeit lighter transmission.

One thing to take note of is that converting a helical gearbox into a straight cut unit is fairly simple, but it’s nearly impossible to go from straight cut to helical.

Once you take the plunge, there’s no going back. Unless you’re ready to swap another transmission.

Do you prefer helical or straight cut gears? Let us know in the comment section below. If you found this post informative, share it with a friend! We appreciate your support!