On the fence about solid and polyurethane engine mounts? You’ve come to the right place. We’ll help you understand the difference between the two and their effects on performance, NVH, and handling.

Unsurprisingly, each motor mount type has unique characteristics, causing them to absorb and transmit vibrations differently.

But the question is, do the benefits translate to a noticeable difference in the real world? Or better yet, is one type of engine mount superior to the other? Does material matter?

Join us as we take a closer look at motor mounts, specifically solid and polyurethane, discussing their pros and cons and finding which type is better.

Why Use Motor Mounts?

Motor mounts play an integral role in reducing your car’s overall NVH levels.

These support the engine and transmission and absorb any vibrations that would otherwise travel through the chassis and cause a noticeable level of discomfort for the passengers.

Stiffer motor mounts offer the least favorable NVH levels, while rubber mounts offer the best. There are several types of motor mounts, ranging from cheap ones made from metal and rubber to electronically controlled hydro mounts.

Their application is defined by the type of car in question, how much it costs, and the type of terrain it’s meant for.

For example, a luxurious streetcar demands high NVH reduction versus a track-focused racecar, where performance takes precedence over comfort.

The former will probably use a softer/dynamic engine mount, while the latter will lean toward a stiffer/solid engine mount.

Polyurethane Motor Mounts

Polyurethane or “Poly” motor mounts offer a level of compromise to address the vehicle’s performance and NVH levels.

The efficacy, however, will depend on the hardness and flexibility of the polyurethane. Poly mounts are usually stiffer than rubber but softer than metal/solid engine mounts.

Rubber mounts are the best for reducing vibrations. They offer excellent damping characteristics and consequently improved NVH levels.

However, since rubber attenuates some of the engine vibrations, there is some energy lost in the process. That’s why it’s not the most ideal setup when performance is the priority.

Polyurethane, however, can be compounded to be harder than rubber. While this translates to better energy transfer between the engine and chassis, the ride quality and NVH levels do take a hit.

The same applies to rubber and polyurethane bushings. The latter will continue to dampen the vibrations, but the efficiency will be noticeably lower than that of rubber.

These qualities make poly mounts an excellent candidate for modified cars. Essentially, you get the best of both worlds. But it comes with its fair share of drawbacks.

Let’s quickly summarize the pros and cons of using polyurethane motor mounts, starting with the pros:

- Better at transferring energy than rubber mounts

- You may notice smoother gear shifts

- Lasts longer compared to stock mounts

- Improved response and feedback from the road surface

- Makes the car feel a lot tighter and more composed than stock

The disadvantages of poly mounts are include:

- Less heat resistance

- Increased vibrations

- Higher cost — bonding of polyurethane to metal is more difficult than with rubber

- Amplified road noise

- May squeak

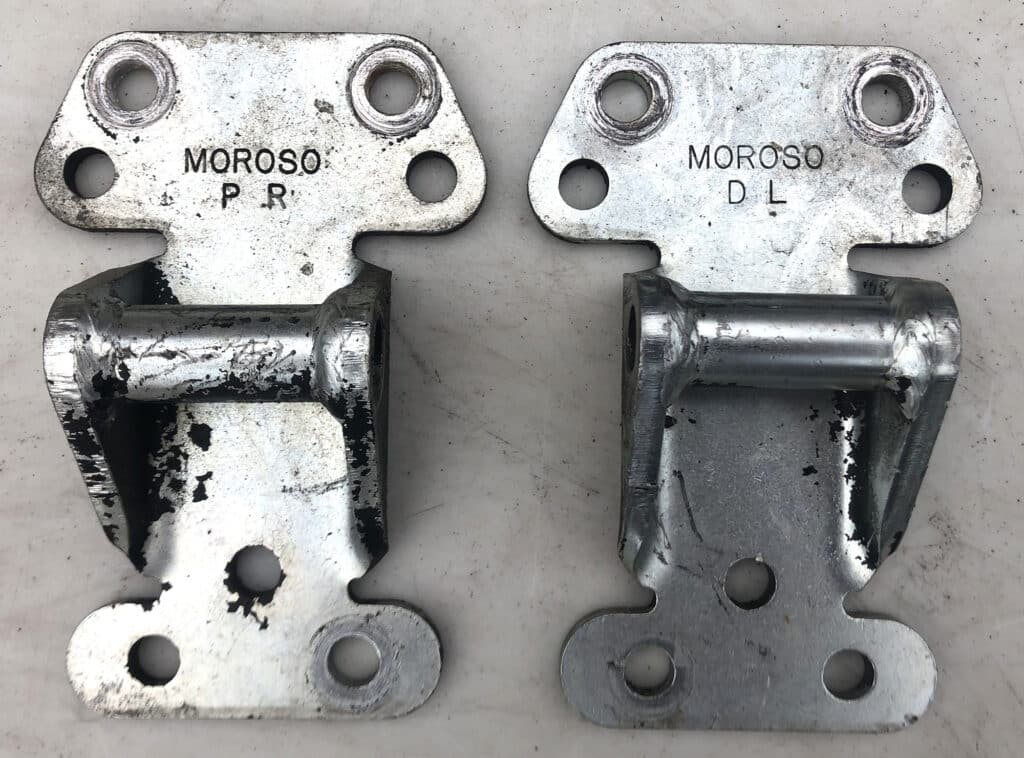

Solid Mounts

If you want the most out of your high hp or whp build, it’s best to go with solid engine mounts. There’s a reason they’re the top choice for different types of race cars.

Solid mounts are certainly among the most aggressive forms of damping as far as NVH levels are concerned. It carries forward all, if not most, of the engine vibrations.

By design, solid mounts transfer energy/torque from the engine with minimal loss of power and, therefore, offer the least amount of damping.

Since there is strong metal-to-metal contact in a solid-mount arrangement, it results in poor NVH reduction, as they flex very little.

But on the bright side, this setup is the most efficient for energy transfer between the engine and chassis. So, unsurprisingly, it’s a common sight in track builds and even some supercars.

But as you can tell, there are pros and cons to using this type of motor mount. Here are a few pros to begin with:

- Little-to-no loss of power energy, improving overall performance

- Offers the least amount of drivetrain flex

- Shifts are crisper

- Better power delivery

- Relatively cheaper than polyurethane

- Best setup for response and road feel

Cons of installing solid mounts include:

- Significantly poor ride quality

- Not the best idea for street use, owing to increased vibrations and road noise

- Stressed-out drivetrain components

Do Motor Mounts Affect Performance?

Motor mounts are designed to hold the engine in place, and if they malfunction, you will feel the effects directly as you drive.

You may notice the engine getting unsettled and sloshing around as you accelerate, turn, or brake hard. Not only that, but motor mounts also affect power delivery and handling.

Imagine a 600-odd-pound engine and gearbox combo moving about as you tackle a corner.

Additionally, bad motor mounts don’t do a great job of absorbing the vibrations, which may lead to delayed shift times and even drivetrain damage, especially at high revs.

Engine mounts are responsible for damping the forces that occur when shifting gears or while decelerating. From a performance standpoint, stiffer mounts help to transmit the forces at the expense of refinement.

In solid engine mounts, there is minimal loss of power, which is not the case in rubber mounts. As discussed earlier, some of the engine torque is absorbed by the rubber. In short, engine mounts will affect performance.

So, it shouldn’t come as a surprise that solid mounts are your best chance at transferring maximum engine torque to the wheels. That’s one reason why racecars solid-mount everything.

Solid Motor Mounts vs Polyurethane vs Rubber

Unsurprisingly, it depends on the use case. A purpose-built track car will benefit from solid mounts because it’s likely not going to spend time driving on broken tarmac. On the other hand, rubber mounts are better suited for street cars.

You might even try poly mounts if your budget allows, and you don’t mind some vibrations seeping into the cabin.

Solid Mounts: Because Race Car

Ideally, solid mounts are best left for track use.

However, according to professionals, if you’ve invested a lot into modifying your car, then poly is the better option, especially if you want a decent compromise between ride comfort and road feel.

Also, it’s advised that you don’t mix and match motor mounts. Try to stay consistent across the board, as the different flex points may lead to damaged drivetrain components.

For most people, stock mounts will do just fine. But for those looking to improve gear shift quality and overall chassis response, poly is a good choice. Get solid mounts only if the car is a dedicated track machine.

Hope you enjoyed reading the article and found it informative. Have you ever regretted installing solid mounts? Let us know by leaving a comment below.