Understanding off-road suspension can be a bit intimidating, owing to the plethora of design choices for various applications.

For instance, there’s a day and night difference between the stuff you see on a purpose-built dune buggy and your run-of-the-mill 4×4 truck. They’re both designed to explore the road less traveled but with varying degrees of proficiency.

So, what’s off-road suspension all about? Is there such a thing as the best off-road suspension setup? Let’s find out.

In this article, we’ll go over the basics of off-road suspension and shed some light on some of the most popular designs you’ll come across.

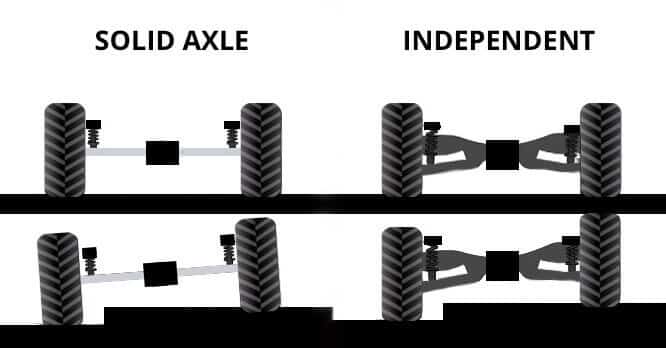

Solid Axle vs Independent Suspension

The most common type of suspension system found in almost all true 4x4s are solid axles.

It is a dependent suspension design used on most vans, trucks, and utility vehicles. A solid axle, otherwise called a live axle, has a shaft that connects both wheels, running from one side to the other with some type of differential sandwiched between.

Because of its design, the setup is not the go-to for most road cars, as an impact on one wheel affects the dynamics of the other. But it does have its advantages, like simplicity and enhanced wheel articulation.

On the contrary, in an independent suspension, the wheels move independently of one another, allowing superior on-road performance and improved ride quality.

There are, of course, several types of independent suspension, ranging from Wishbones to MacPhersons to multi-link arrangements.

In most SUVs and trucks, OEMs use a mix of both designs, preferring an independent front and solid axle rear.

Factory 4x4s often use live axles both at the front and rear, settling with a solid-axle-independent hybrid owing to packaging and stability reasons.

Another off-road suspension layout is the fully independent rear. The setup, however, isn’t cheap and therefore, not a common sight in the rock-crawling community.

But you often find it on bespoke desert racers, running custom chassis design and suspension arrangements.

Coilover vs Leaf Springs

A 4×4’s solid axle should ideally move in a vertical direction while putting down the power.

There shouldn’t be any kind of axle wrap, lateral, or fore-and-aft movements, as these could affect the handling and durability.

Because of its design and arrangement, a leaf spring system controls both lateral and sideways axle movements quite effectively.

Axle wrap is also mitigated, but its effectiveness is largely based on the leaf’s thickness and spring rate.

In a coilover solid-axle suspension, which is more common these days, the spring and damper system only takes care of the sprung weight, meaning the axle is vulnerable to undesirable multi-directional movements.

This is addressed using a multi-link arrangement with or without a Panhard.

But why use coilovers when leaf springs are clearly better? Firstly, the former offers better ride quality. Secondly, while leaf springs do seem advantageous on the off-road front, they are quite heavy and require a lot of space.

But in small and medium-sized trucks and 4x4s, space is hard to come by, so a coilover solid axle with a multi-link arrangement is preferred.

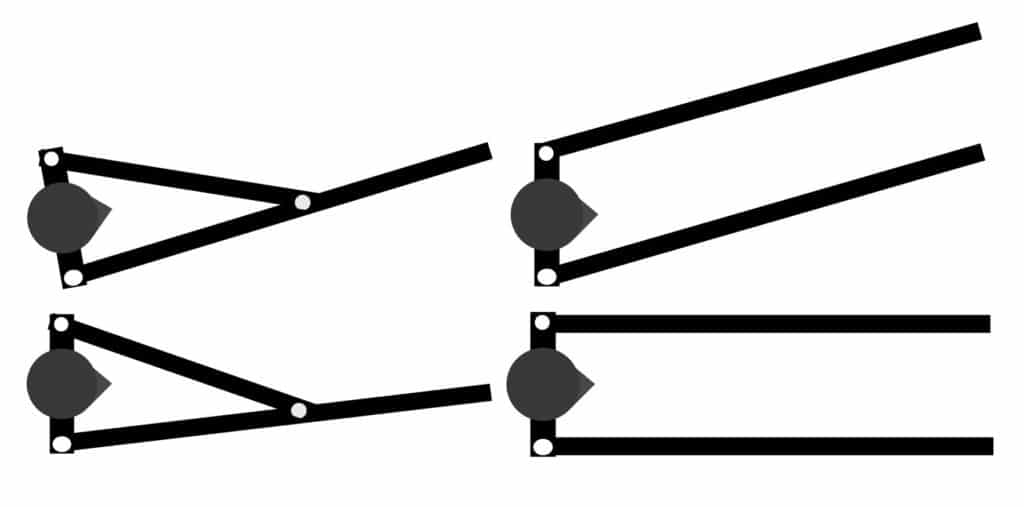

Solid Axle Multi-Link: 3-Link vs 4-Link vs Radius Arm

A solid axle multi-link suspension is a hybrid design commonly seen on most trucks with a coilover suspension.

To know why you’d want this design or its various arrangements, you’ll require a better understanding of 3-link vs 4-link suspension. For now, let’s understand the basics of these common solid axle multi-link setups.

A 3-link suspension, as you might’ve guessed, has 3 links that hold the axle and chassis together.

Oftentimes, you’ll see a 4th link, which is nothing but a Panhard bar integrated into the setup for better stability.

In terms of configuration, you’ll find some builds running a Wishbone 3-link or a parallel 3-link with a Panhard bar.

On the other hand, a 4-link suspension has 4 individual links (2 upper and 2 lower), with the ends of each rod bolted to the axle and chassis, respectively.

The upper links prevent the axle from rotating, while the lower links address the axle’s fore-and-aft movements.

The basic setup can be either parallel or triangulated, with the latter split into single and double-triangulated designs.

In a Radius arm arrangement, your upper control arm is connected to the lower control arm, which is then bolted on the frame.

Radius arms, considered among the simplest of multi-link off-road setups, reduce the fore-aft movements and axle wrap in a coil-sprung solid axle design.

You’ll often find it paired with a Panhard bar to offer more lateral stability.

Lift or No Lift?

Adding lift unlocks more ground clearance and the potential for increased suspension travel. It offers better approach and departure angles, while also allowing you to run bigger tires.

However, lift impacts the handling quite dramatically, especially when it’s not tuned properly to suit an off-road suspension design.

You may try body lift kits that use spacers or go with a proper suspension lift kit. The former is more cost-effective but doesn’t offer as many benefits as the latter, which, on the other hand, can be a lot more complex and expensive.

Either way, use quality lift kits and ensure installation is done by a professional. You don’t want to ruin the suspension geometry.

It’s important to know that by changing the ride height, you’re significantly altering the suspension link angles, stability, ride comfort, and so on.

Your suspension setup, whether OEM or aftermarket, is employed to keep a relatively constant pinion angle at varying levels of suspension travel.

Even the slightest change in the link angles and measurements would create havoc. It can mess up the caster and camber angle too.

The best way, of course, is to factor in ride height and ground clearance when designing your suspension layout. For IFS vehicles, there’s always an option of installing a diff drop kit if need be.

Depending on your build requirements, you may use adjustable brackets/Panhards to go back and forth between different setups. Of course, finding the right balance might require a bit of trial and error.

Concluding Thoughts

There is no such thing as the perfect suspension. Design a layout that best fits your vehicle and your driving needs. Choosing the right suspension setup is almost always a matter of space and cost.

While all off-road arrangements have pros and cons, deciding on which one to use boils down to your vehicle’s steering, driveline, differential layout, and available space for installing the suspension setup.

Of course, cost and complexity are also worth considering.

Jeep live axle or Toyota IFS — what would you pick? Let us know by leaving a comment below.