We’ve come a long way from the days of old suspension tech. A time when your only options were wafty old Cadillacs that drove like boats or sports cars that could rattle your spine.

Comfort and handling were almost never mutually exclusive.

But modern suspension components are far more sophisticated in contrast, and they offer a blend of performance and comfort like never before. One such component is the control arm.

Most discussions around suspension modifications are limited to coilovers and lowering springs. Few talk about control arms.

In this article, we’ll discuss upper and lower arms in detail, by taking a closer look at what they do and how they work. We’ll also briefly touch on adjustable control arms and their effects on camber and wheel alignment.

Additionally, you’ll also learn about the possible symptoms of failing control arms and the hazards associated with it.

What Do Control Arms Do?

Control arms are integral to the automotive suspension system mainly because they serve as a structural link between the wheels and the chassis.

One end of this structural link is bolted onto the chassis in a way that allows it to pivot up and down.

The opposing end connects to the steering knuckle which moves left and right thanks to the tie rod and other steering system components.

Together, this mechanism allows the wheels to move up and down; and turn from left to right, which is what makes the car drive the way it is supposed to.

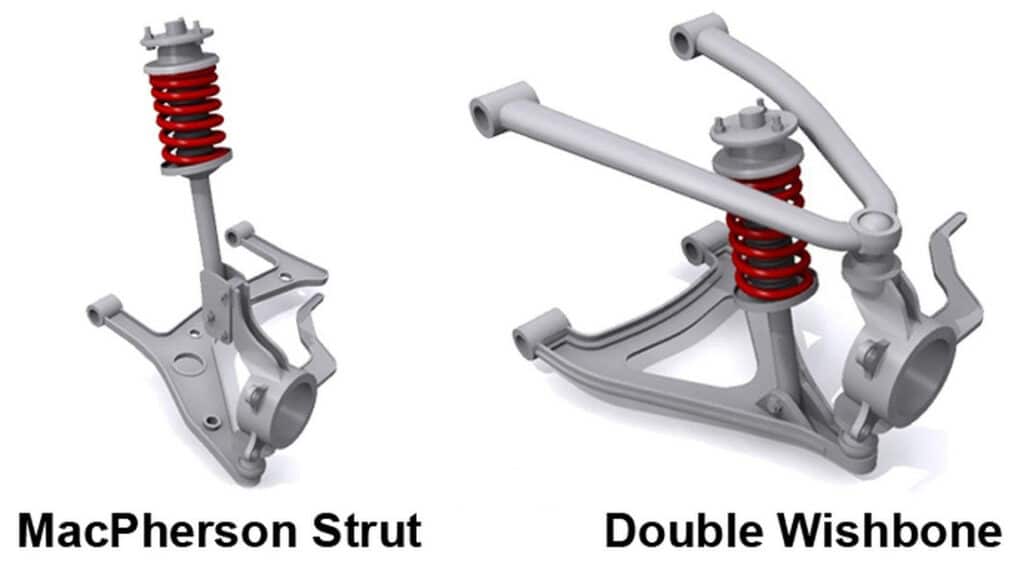

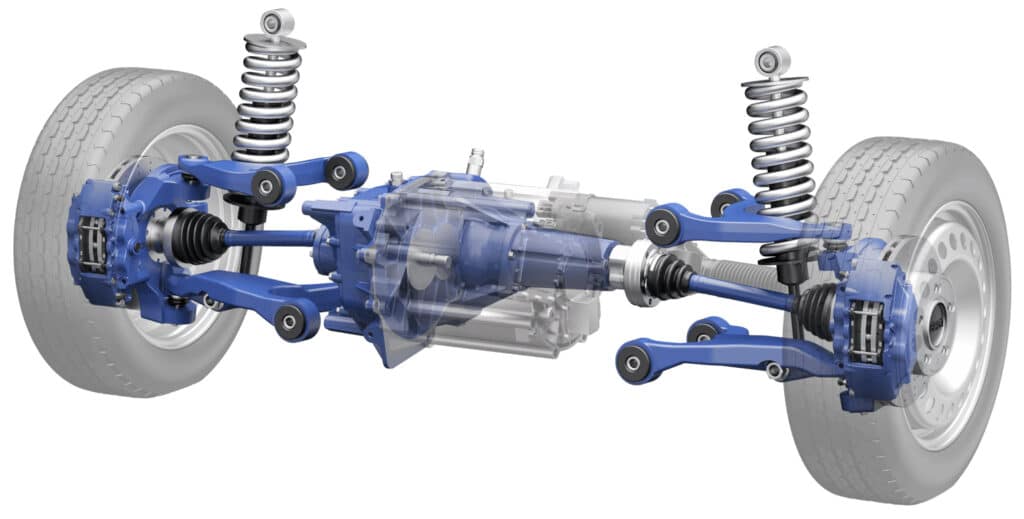

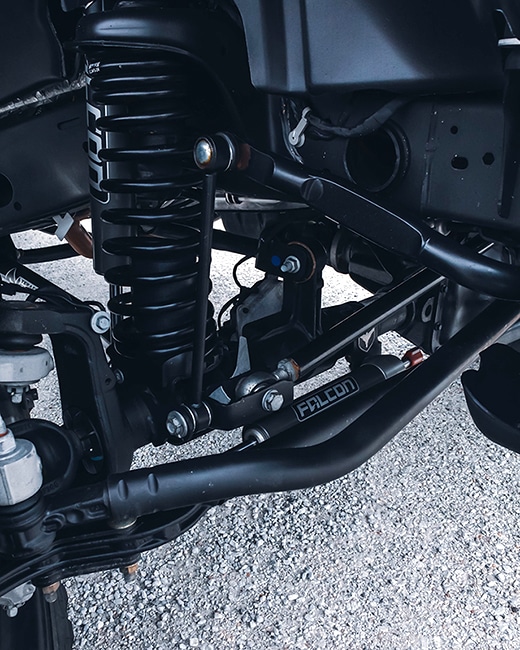

In double wishbone suspension systems, both front wheels (and rear wheels in some cases) have two control arms each, with two mounting points on the chassis.

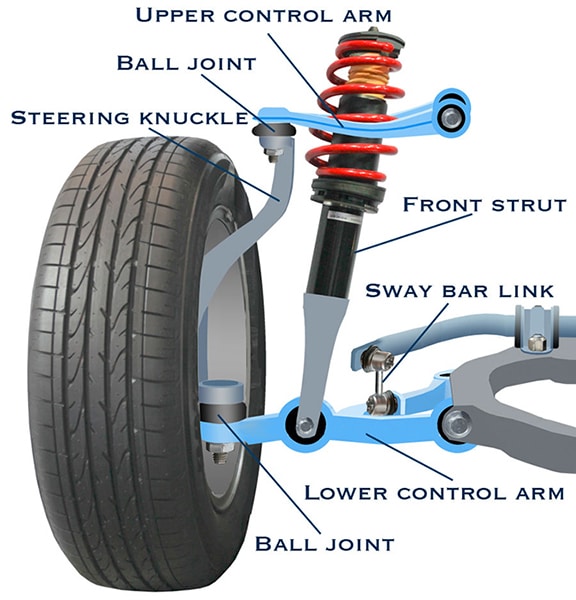

As obvious as it sounds, the upper control arm connects to the topmost part of the steering knuckle, and the lower control arm connects to the lower part of the steering knuckle.

Both these points of contact are mobilized by means of a ball joint. If you’re wondering how many control arms your car has, knowing what type of suspension it has is one way of finding out.

Most production cars are equipped with both upper and lower control arms, but some cars have only lower control arms. Some cars have just one control arm at each wheel.

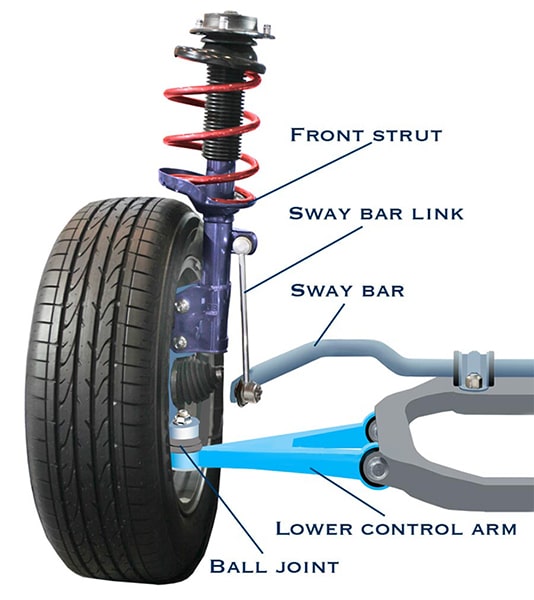

In MacPherson strut-type suspension systems, the upper control arms are replaced by a strut which is supported on the top via a direct mount to the body of the car.

This mounting point is called a strut bearing. In other words, the strut itself fulfills the role of an upper control arm.

However, with independent or double wishbone suspensions, the upper and lower control arms have the spindle connecting to both arms via ball joints.

Closely inspecting an independent suspension’s design will paint a clearer picture. Components and attachment points of an independent suspension system include:

- control arms,

- springs,

- damper,

- sub-frame/chassis,

- brake assembly, and

- steering linkages (only on the front wheels).

In terms of placement, you’ll find the control arms located right behind the wheel hub and brake assembly.

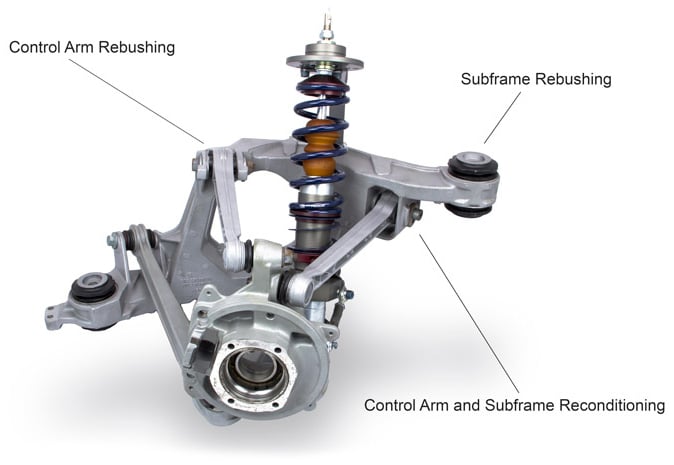

These are connected to the frame with the help of bushings that allow them to move up and down.

The opposing end of the control arm is attached to a spindle (or knuckle) on which the brake rotor is bolted.

Upper vs Lower Control Arms

The purpose of control arms is that they allow for more steering feedback while ironing out the imperfections of the road as much as possible.

Control arms play a crucial role in the stability and overall driving feel.

More importantly, control arms are designed to allow drivers to steer while simultaneously moving the wheels (either up or down) according to the road surface.

In short, control arms ensure that the steering, suspension, and chassis work together as a cohesive unit.

The control arm bushings take care of longitudinal movements, while the ball joints located at the opposing end of the control arm allow the spindle to steer the wheels.

These bushings typically consist of an outer metal sleeve, a durable rubber or polyurethane bushing, and an inner metal sleeve.

The spindle and the wheel are attached to these ball joints, so whenever the steering wheel is turned, the tie rod pivots the spindle which turns the wheels as a result.

And when your car is going over rough terrain, the control arms, along with the coil springs and dampers (sandwiched between the upper and lower control arms) soften the ride by absorbing the impact.

And lastly, when you’re driving through rough terrain and turning at the same time, the front control arms are responsible for both steering and suspension duties.

When this setup is present on all four wheels, it allows for independent suspension travel, offering noticeably better ride comfort and handling.

The Difference Between Front and Rear Control Arms

When it comes to cars that have control arms on all 4 wheels, a common question that arises is whether or not the control arms on the front and rear are the same.

Front control arms have the additional duty of housing the steering components, which requires a completely different design.

As for the rear control arms, their job is limited to carrying out general suspension duties, so they’re designed accordingly.

For instance, in a rear-wheel-driven vehicle, designers have to consider the differential and half shafts before setting up the rear suspension system.

Engineers have to design the entire suspension after factoring in additional stresses, packaging space and proposed usage.

The design differs drastically depending on whether it’s an off-road vehicle or a simple load carrier, or a flat-out racecar.

Do All Suspension Types Utilize Control Arms?

Not all cars have the same type of suspension. Some of the variations include:

- Rigid axle

- Elliptical leaf spring

- Multi-link

- Double wishbone

- Trailing arm

- MacPherson strut

- Independent suspension, and many more.

Some of these suspension types are designed for economy cars, while other applications range from trucking to track use.

Almost all types of road cars include control arms as a part of their suspension design. Commercial vehicles, on the other hand, are designed to carry loads and so they fair well with leaf springs.

Race cars use push-rod suspensions because they have a low ground clearance and ride height. These cars are all about high-speed stability and have little to no body roll.

MacPherson strut-type suspension systems lack upper control arms, while other forms of independent suspensions have both upper and lower arms.

Control arms, in general, are typically A-shaped, L-shaped, or wishbone-shaped. However, designs vary based on the suspension geometry.

Double-wishbone suspension is commonly seen on high-end cars and has control arms shaped like wishbones. You could say that wishbone arms are another form of A-shaped control arms.

These control arms have the narrow end attached to the wheel assembly and the broader ends to the frame of the car. The narrow end usually features a ball joint, and the wider end houses the bushings.

For L-shaped control arms, the design is fairly similar.

However, instead of having two chassis mounts, these control arms have a single mounting point on one side and a ball joint on the other, effectively connecting the chassis and the steering knuckle.

Most low-end cars come with L-shaped control arms, while A-shaped arms are common in mid to high-end cars, depending on the material used.

Steel control arms are inexpensive and flex under stress, meaning fewer accounts of breakage or cracking when off-roading or driving with heavy loads. But rust is a drawback.

Aluminum control arms are made from cast aluminum. They are quite sturdy and lightweight.

They don’t corrode and have a longer lifespan. The downside is that aluminum control arms can’t flex as much as steel and they’re prone to cracking.

Cast iron is another popular material for control arm design. Cast-iron control arms are sturdier and lighter than steel and they can withstand quite a lot of abuse. These are commonly found in trucks and SUVs.

Adjustable Control Arms Explained

Most OEM control arms can be set at only one position. Enthusiasts looking to improve the ride quality and handling should seriously consider aftermarket control arms.

Adjustable control arms will replace your stock control arms and provide additional adjustment. The setup is especially useful if you have a lowering kit or lift kit installed.

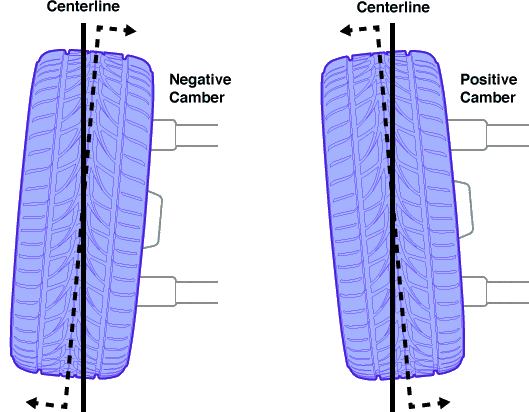

Installing aftermarket adjustable control arms allow you to adjust your camber angle. This is an important step if you want your tires to maintain traction and wear evenly.

The same applies to both positive and negative camber. Check out our articles on the subject for more details about camber angle.

Impact on Wheel Alignment and Camber

Every inch of deflection in ride height will change wheel alignment and suspension angles will get altered significantly.

In other words, once your car has been lifted or lowered, the suspension geometry is permanently changed from OEM specifications.

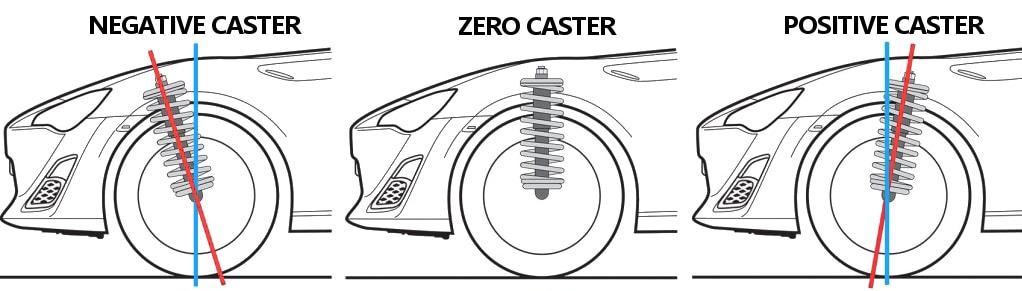

This means the wheel loses its factory caster angle and camber settings because OEM control arms don’t have enough adjustability to offset the change in wheel alignment.

This is where adjustable control arms come in. Installing these and adjusting them correctly will allow you to fix the clearance and alignment issues that come along with lowering or lifting your car.

Also, it’s an absolute must to get your wheels aligned and corner balanced after installing adjustable control arms. The tolerances vastly differ, and wheels should be calibrated before leaving the shop.

Another notable benefit is that adjustable control arms weigh lesser compared to OEM control arms.

This reduces unsprung weight and improves ride quality as a result. Reduced unsprung mass leads to better steering feedback handling.

Symptoms of a Failing Control Arm

The first sign of failing control arms is judder and vibration. You’ll notice your wheels wobbling slightly when you go hard on the gas.

When the bushings in your control arms wear out, they can no longer hold your wheels firmly in place, especially when they’re under load.

The vibrations from wobbling wheels can be felt on the steering wheel quite noticeably. It’s worth mentioning that faulty steering system components can also cause vibrations.

If your car keeps pulling to one side, that can also be an indicator of faulty control arms. By design, control arms have rubber bushings surrounding metal parts.

Wear and tear on the bushings will inevitably cause metal-to-metal contact, which will lead to creaking or clunking. This sound is the same as many other suspension components will make, like coilovers.

Look out for these sounds when accelerating, taking a sharp corner, or driving over a broken patch of road. Road testing is the best solution to finding out whether your car has faulty control arms.

Driving with failed control arms will have adverse effects on wheel alignment and tire wear. Bent control arms with worn ball joints and bushings can lead to wobbly wheels which is a consequence of improper wheel alignment.

Poor alignment will also lead to prematurely or unevenly worn-out tires. What you will notice for sure is the general lack of driving comfort and stability.

Control arms have bushings that dampen vibrations and help to reduce harshness.

What Causes Control Arms to Fail?

Sudden acceleration or hard impact from driving over potholes and bumps can cause your control arms to fail prematurely.

That’s because they pretty much bear the entire load of your car, albeit with help from springs, dampers, and wheels.

Quite a bit of flex gets induced in the control arms when you accelerate heavily from a standstill or when you drive over a pothole at high speed.

Control arms are not primary load-bearing components like wheels, springs, or dampers. But they play a secondary role and so they are designed accordingly.

Avoiding rough patches and deep potholes on the street is recommended. Adverse road conditions will ruin the ball joints and can even cause them to break loose.

This is especially true with economy cars that aren’t subjected to the kind of stress tests that trucks and SUVs go through.

For example, purpose built off-road vehicles like 4Runners and Wranglers have stronger internals than soft-roaders like RAV4s and Renegades.

This is why you can install a Tacoma lift kit and chuck on some big tires but not break anything.

The same holds true for cars like the BMW M3 and Porsche 911. These cars are designed to take the abuse.

Another potential cause for control arm failure is rust and corrosion. Prolonged exposure to moisture will cause the surface of your control arms to rust.

Over time, the rust wears the metal down, eventually lowering its structural rigidity. This is a concern especially if your car has steel control arms and if you live in a place where it rains a lot.

Lastly, negligence and lack of maintenance is perhaps the most important factor. Whatever you do, make sure your car is looked after properly.

If you want your control arms to last, then it’s always best to perform routine maintenance of your suspension components.

Concluding Thoughts

Understanding the basics of how your suspension components and other car parts work will go a long way in your automotive hobby.

Check out our guide to understanding how coilovers work and the difference between struts and coilovers to familiarize yourself with these components.

What’s your favorite type of suspension? Let us know by leaving a comment below. If you enjoyed reading this post, consider sharing it with your friends on Reddit, Facebook, or any of your favorite online communities.

We appreciate your support!