Engine technology is a fascinating subject. Every decade or so, automakers come up with ground-breaking innovations that somehow eke out more power and fuel economy.

Look at the Toyota GR Corolla. The turbocharged 3-cylinder hot hatch produces 300 horsepower and offers 29 mpg of combined fuel efficiency — numbers unheard of 30 years ago!

However, there were technologies of a similar nature that kept pushing the boundaries of performance, efficiency, and emissions in that era.

One such example is Nissan’s NEO VVL. The technology was quite innovative for its time. So, how does it work? More importantly, why did Nissan use it? Let’s find out.

How Does Variable Valve Lift Work?

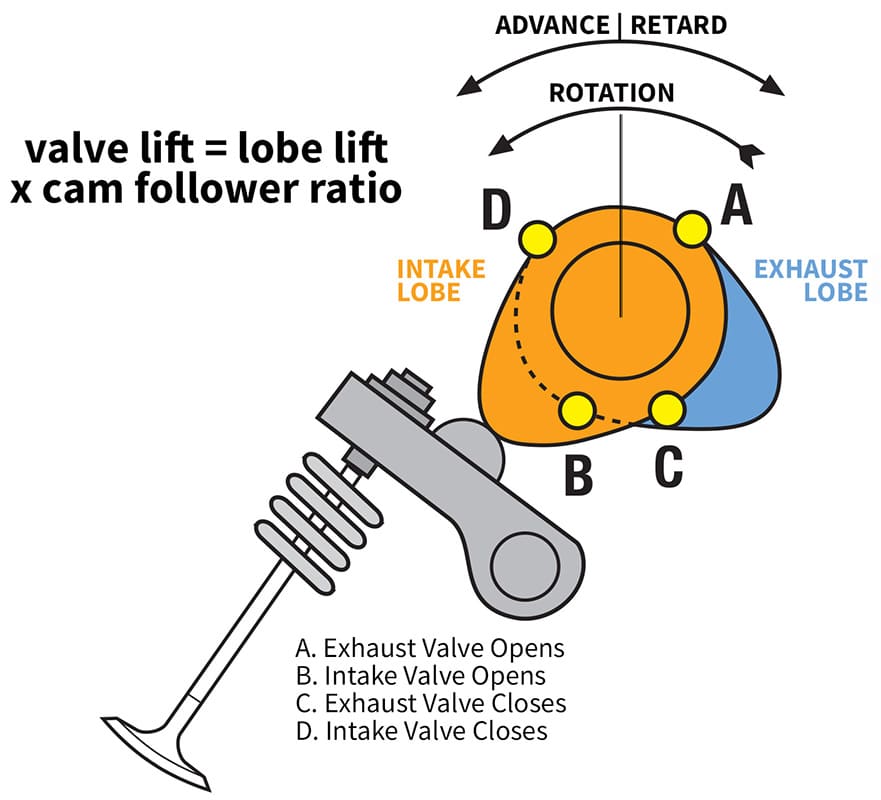

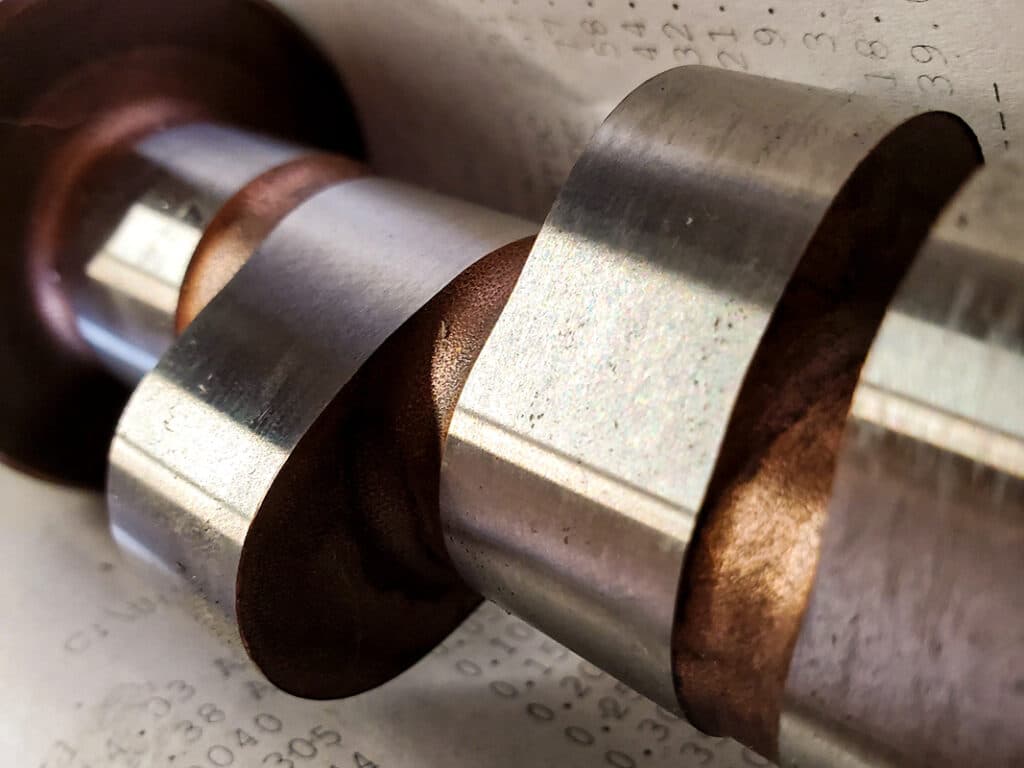

By definition, variable valve lift (VVL) refers to changing the valve’s height (lift). Before understanding VVL, let’s understand what variable valve timing is and how it works.

As you might have guessed, VVT involves altering the valve timing (opening and closing) to tailor to both low and high rpm requirements.

VVT, however, is not just limited to valve opening and closing but, in some cases, influences its duration and lift as well, depending on the design.

So, in a way, VVL is a form of variable valve timing, which falls under the VVT umbrella. It’s worth mentioning that there are two types of VVL: discrete and continuous.

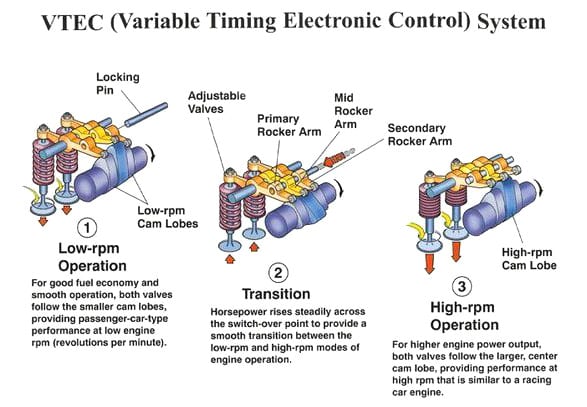

The former typically involves OEMs employing their own implementation of the cam changing/switching method to alter valve lift by fixed amounts.

Continuous VVL, or CVVL, is generally more complex and relies on a battery of controllers and other components to continuously vary valve lift.

The complexity of the system is design-dependent and often varies between manufacturers. Examples of discrete VVL include Honda’s VTEC, Toyota’s VVTL-i, and Nissan’s NEO VVL.

On the other hand, BMW’s Valvetronic, Toyota’s Valvematic, and Nissan’s VVEL seen in the VQ37VHR engine are technologies that feature continuous VVL.

What Is Nissan’s NEO VVL Technology?

NEO VVL, or Nissan Ecology Oriented Variable Valve Lift and Timing, is the company’s take on variable valve timing and lift.

Having better control over the valve timings allows the engine to be further optimized for power and efficiency.

Nissan’s NEO VVL setup incorporates variable valve lift (discrete) and is commonly referred to as VVL in the community.

While the SR16VE was the first engine to receive NEO VVL, the SR20VE was the one that popularized the technology,

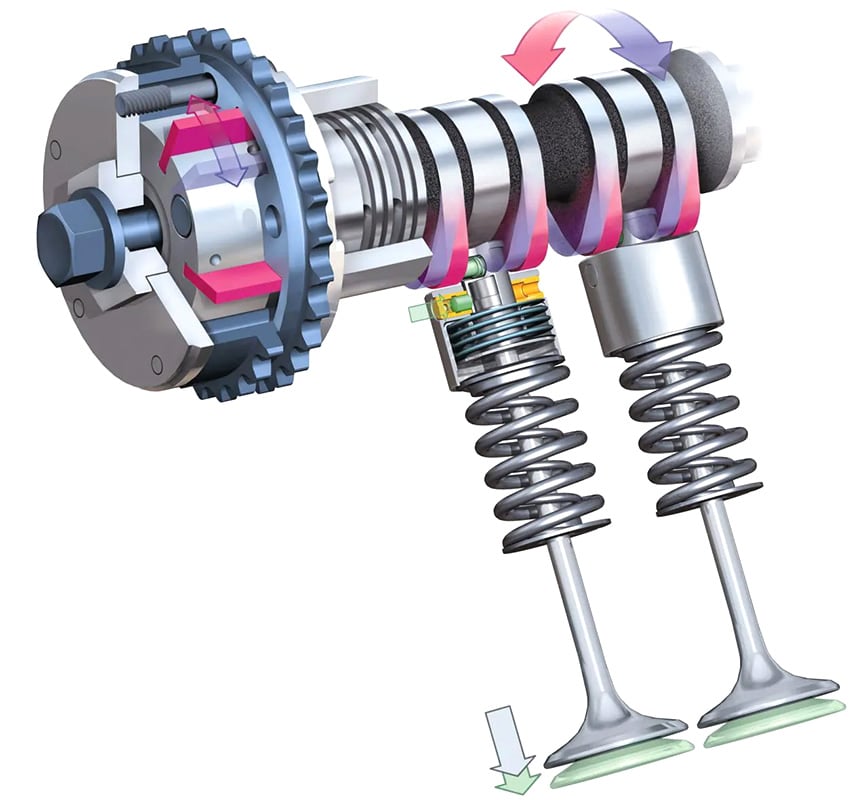

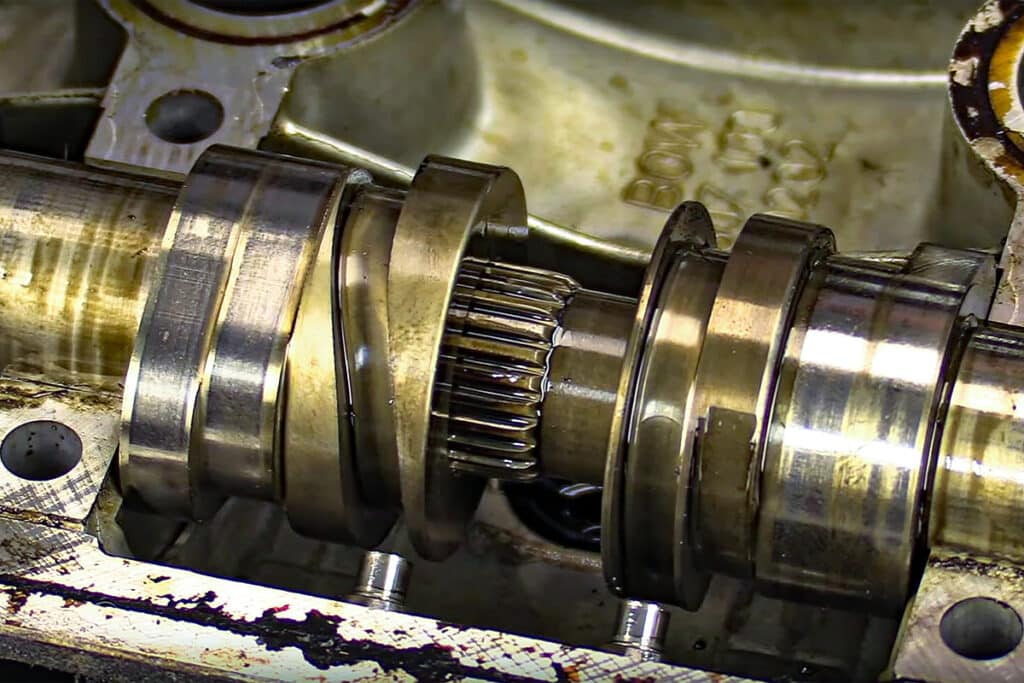

As for its operation, the variable valve timing is achieved by changing the cam lobes via hydraulic pressure, similar to Honda’s VTEC and i-VTEC.

However, Nissan engineered the system such that the intake and exhaust cam profiles can be triggered independently of one another for a flatter and smoother power band.

Are VVL and VTEC the Same? What About VCT and i-VTEC?

If the true definition of the word is taken into account, then VTEC is a form of VVL. Ergo, the same thing as Nissan’s NEO VVL.

But since Nissan’s system is a bit more consistent in its power delivery, you wouldn’t notice the “kick” as you would in a VTEC setup.

However, if you compare it to Nissan’s NVCS or VCT (Nissan Valve Timing Control System), then it’s different. Nissan’s NVCS or VCT/N-VCT is more similar to i-VTEC without the valve lift technology.

Honda’s VTEC system only controls valve lift and duration, whereas i-VTEC incorporates VTC (Variable Timing Control) with VTEC.

Achieved through cam phasing, VTC (much like NVCS) advances or retards valve lift by rotating the camshaft relative to the crankshaft position and angle.

VTEC, on the other hand, works by cam changing, similar to other forms of discrete VVL.

Final Thoughts

Variable valve timing can be confusing, especially since OEMs come up with fancy acronyms to market what is essentially the same technology.

Of course, they may vary slightly in operation and design, but the principle remains the same. The situation is not that different when it comes to VVL.

While all VVLs could be categorized as a form of VVT, the converse isn’t always true. All VVTs are not always designed with variable valve lift in mind.

Toyota’s VVT-i, for example, although a form of VVT technology, is a cam phasing system that controls valve timing and not valve lift, unlike Nissan’s NEO VVL.

Do you prefer the distinct VTEC kick or the VVL’s linear power delivery? Let us know by leaving a comment down below.