The term stroker engine is thrown around quite a lot in the world of motorsports and aftermarket upgrades. Especially among the mechanically inclined enthusiasts who still practice the lost art of increasing engine displacement.

We all know that there is no replacement for displacement. But sadly, the heydays of big-block V8s are long gone. The automotive industry has gravitated towards lower-displacement turbocharged four-bangers for fuel efficiency and lower emissions.

While that move was good for the environment, it took away the things we love about high-displacement naturally aspirated engines — instant response, refinement, and sensory drama.

Engine builders, however, are not ready to throw in the towel, not yet. They’re obsessed with the idea of utilizing every last cubic centimeter engines have to offer — whether the design allows for it or not.

Bigger fuel injectors, high performance turbos and remaps all have their place. But what if you already have a maxed-out engine and still need more oomph? Or maybe you want to keep it simple and have the best possible NA build? Enter stroker kits.

This article is all about stroker engines. We go over their pros and cons, discuss stoker kits, and touch on possible alternatives. Let’s take a look.

What Does “Stroker” Mean?

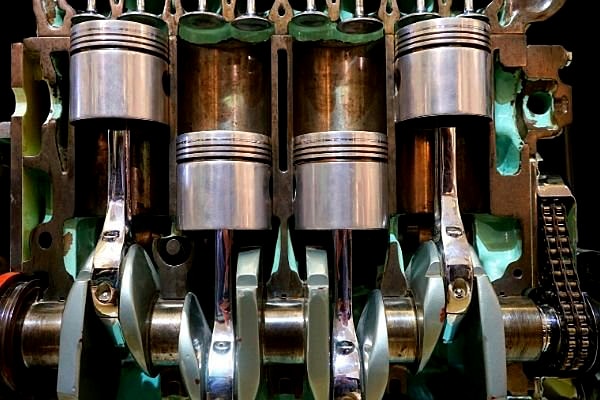

Simply put, a stroker engine is one that has the stroke of its crankshaft increased beyond stock specifications.

These days, stroker engines can be built with the help of aftermarket crankshafts and stroker kits which save a lot of time and effort.

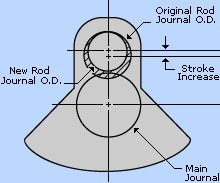

Before aftermarket crankshafts and stroker kits were readily available, the only ways to lengthen the stroke of an engine was to install a crankshaft from a different engine with a larger stroke or rely on the good old offset grind method.

This involved grinding down the crankshaft’s rod journal to a smaller diameter, and to a centerline further away from the actual center of the crankshaft. But there was only so much power to be made with this method. Besides, it’s extremely labor-intensive, expensive, and compromises the structural integrity of the crankshaft.

What’s the Point of Increased Piston Stroke?

Torque! Lots of it. Once the piston has more distance to travel, the reciprocating motion adds more torque.

Here’s an analogy for more clarity — have you ever tried loosening a stubborn lug nut?

You must’ve noticed the difference between using a standard wrench and an extended wrench. The shorter wrench requires more effort, while the longer wrench can loosen the nut without much force.

The force acting on the lug nut is torque, and it is a function of distance, more specifically, perpendicular distance. The longer wrench has more distance between the lug nut and the point of application, so it generates more rotational force, i.e., torque. On the other hand, with the shorter wrench, you need to apply more force to generate the same amount of torque.

Rotational force is what moves the vehicle. That’s why heavy-duty trucks use diesel engines rather than gasoline. Firstly, they’re more economical, and secondly, diesel engines for the equivalent capacity produce more torque.

That’s because diesel engines utilize compression ignition and have a fairly long stroke. This inherent design advantage makes them ideal for high-torque applications. However, there are downsides; horsepower takes a hit, it weighs more, and the engine isn’t the most exciting to drive, owing to lower redlines.

So we’ve established torque is important for low-end grunt. Now we need to look at how stroke lengths determine horsepower and torque. For that, let’s consider two engines having the same displacement but different stroke lengths.

Shorter stroke lengths allow the engine to rev higher and faster, generating more horsepower. On the flip side, an increased stroke would result in improved torque, but engine revs could drop as the piston has to travel more. By design, short-stroke engines are less torquey, while long-stroke engines have a weak top-end.

Larger displacement gasoline engines have an upper hand when it comes to torque. A 3.0 L engine will make more power and torque than a 2.0 L engine, provided they’re of the same configuration, and the bore-stroke ratio remains similar.

This is where stroker kits come in. You can have the 2.0 L produce better power and torque figures through a small bump in displacement.

Although, the amount of power produced depends on how much you intend to increase the capacity. A 351 cu.in (5.7 L) Windsor small-block can be stroked to a whopping 429 cu.in (7.0 L), and that’s with the same engine block!

If you’re thinking JDM, don’t worry, there are several aftermarket stroker kits available for SR, RB, and JZ engines.

Stroker Kits For SR20, RB26, and 2JZ Engines

All three engines are quite popular among enthusiasts for their durability and range of aftermarket support.

Nissan’s SR20DET engine has an all-aluminum design with 86 mm bore and 86 mm stroke. The 2.0 L Inline-four engine puts out 205 horsepower and 203 lb-ft of torque. Later versions, dubbed black top and red top, produced 220 and 250 horsepower, respectively.

As for stroker kits, HKS makes one specifically for the SR20DET which provides improvements in torque from low to medium speeds. It also bumps up power output making it an ideal choice for drag racing. Plus, the kit utilizes forged pistons and connecting rods, with bore sizes ranging between 86.5 mm to 87 mm.

This pushes the engine to 2.2 L but requires cylinder boring. The engine might not be strong enough during high RPM loads after re-boring. So, HKS offers a thick metal sleeve for the cylinder wall re-sleeving process to replace the cast sleeve, offering better reliability.

On the other hand, HKS has another slightly cheaper alternative with just a forged crank, offering a stroke length of 91 mm. This one, however, doesn’t require additional boring. You can buy these separately or together, depending on your budget and power requirements.

The RB26DETT engine features an Inline-six layout with a cylinder bore of 86.9 mm, and a piston stroke of 73.7 mm. The 2.6 L twin-turbo engine manages to pump out 276 horsepower and 260 lb-ft of torque. However, later versions produced 316 horsepower, with torque jumping to 289 lb-ft. Plenty of stoker kits are available for the RB26, but this one is from Brian Crower. The kit can push the RB26’s capacity up to 2.9 L.

It includes a 79 mm stroke billet crankshaft, H-beam connecting rods, and forged pistons with all the auxiliary components. Available piston sizes range from 86 mm to 87 mm, but custom orders are available. HKS also offers stroker kits for the RB26, with power ratings up to 1,200 hp. The kits can be bought separately or together, depending on your budget. Bore and stroke are 87 mm and 77.7 mm, respectively, with the engine capacity getting bumped to a maximum of 2.8 L.

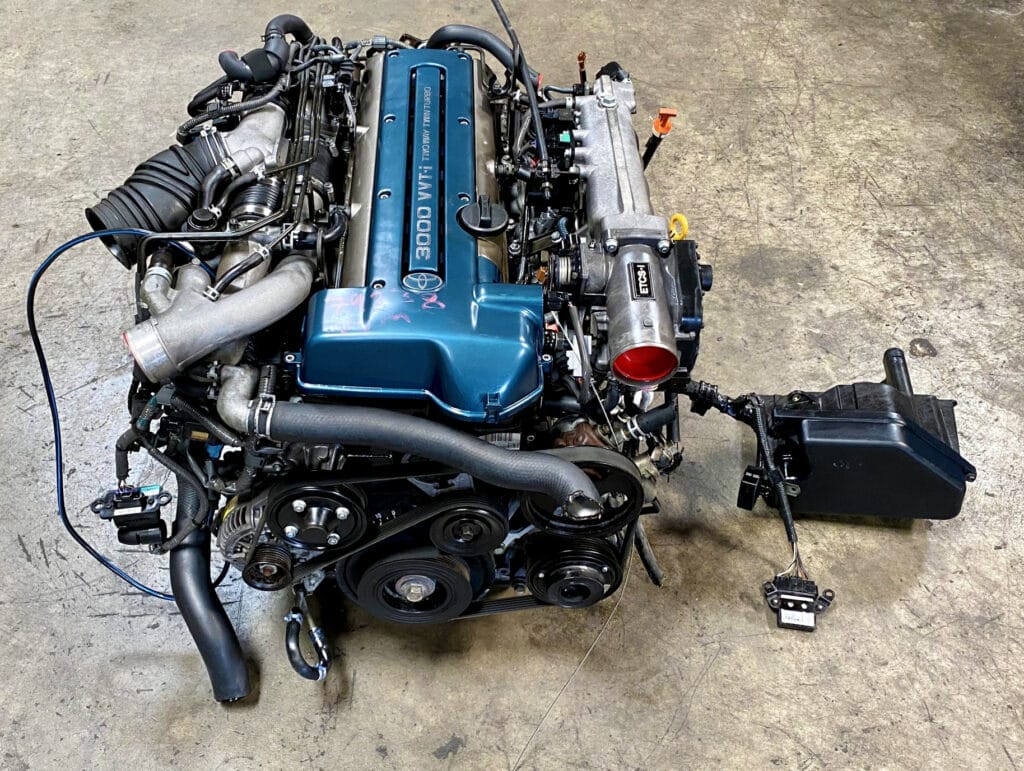

Toyota’s 2JZ-GTE incorporates a closed deck design with cast-iron block and aluminum cylinder heads. Stock bore and stroke stand at 86 mm each. The 3.0 L straight-six motor puts out 320 horsepower and 316 lb-ft of torque and makes use of two sequential turbos.

As for available stroker kits, there are quite a few on sale. Brian Crower, Tomei, and HKS offer stroker kits with different specifications. Tomei happens to offer the most displacement at 3.6L. The unit comes with custom pistons having 87 mm bore and 100 mm stroke. Brian Crower, on the other hand, has stroker kits up to 3.5L.

These come in a variety of bore and stroke lengths, with the top-spec version getting 87 mm and 96 mm, respectively. However, BC offers custom piston sizes, depending on the compression ratio you’re running. Opting for the HKS kit will offer a maximum displacement of 3.4L, with an 87 mm bore and 94 mm stroke. HKS claims 1,000 plus horsepower to be possible with the kit.

All kits come with forged pistons, connecting rods, and billet crankshafts with counterweights. Extensive research and development have been carried out by all engine builders, so potential buyers shouldn’t have to worry about longevity all too much.

If you’re wondering about costs, complete kits range between $4,000 to $20,000! That said, you can look to buy them separately (crank kit, piston kit..etc.) and consider it a long-term build. This helps cut down costs significantly.

Now that we’ve taken a look at some of the available stroker kits, let’s focus on the pros and cons of having a stroker engine. As you can probably tell, it’s not all sunshine and rainbows.

Pros and Cons Of a Stroker Engine

Since we’ve been glorifying stroker engines for quite some time, let’s start with some of its drawbacks. Chief among which is cost. If you haven’t yet noticed, the process of stroking an engine isn’t cheap.

As we mentioned above, costs can range between a few thousand dollars to a five-figure sum, depending on your build. And mind you, that’s just the engine costs, add in another couple of grand for labor, and it all becomes one expensive exercise.

Another concern you may have is reliability. OEMs spend billions of dollars on research and development to arrive at an engine design. Having someone take it apart and install new internals may not sound all too reassuring.

That said, technology has come a long way since the early days of engine stroking. Reputed manufacturers spend quite a lot of money on developing aftermarket parts. So, the idea of a stroked engine breaking down easily is highly unlikely, provided the work was done by a professional using quality parts.

Sacrificing the top-end is another downside. But, not all stroker kits are designed that way. If you’re swapping the crank for better stroke, the top-end can suffer. But it can be fixed. Using larger pistons with an increased bore should compensate for the lack of power in the higher rev range. So it really boils down to the setup you are running.

Moving on to the pros, stroker engines offer a significant boost in power. As you can see from the examples above, squeezing 1,000 plus horsepower from SR, RB, and JZ is fairly easy with stroker kits. What’s more, you get the added reassurance of stronger internals should you find the need to squeeze out more.

Also, you can mix and match to arrive at your desired engine character. Say you’re into drifting, the engine requires more low-end power for increased wheel spin. But you’re not overly concerned about the top end, so swapping out the crank for a longer stroke should be ideal. On the other hand, if your use case involves high horsepower outputs, a full stroker kit can get you improved power figures.

The added torque requires lesser gear changes, in the case of street driving. This is especially a boon for three-pedal drivers stuck in stop-and-go traffic. If you’re into circuit racing, ones with tight turns and gradients, then the idea of having a torquey engine is a smart move. You can be on power almost all the way without having to ring it every time.

Okay, now you have a fair idea about stroker engines, so it’s time to look at other methods worth considering.

Stroker Engine Alternatives

Yes, there are few alternatives to stroker engines. Engine swaps are something you can look into. Of course, cost-wise engine swaps are almost on par with stroker kits.

Cylinder boring is another possible solution. Yes, you’re increasing the engine capacity, but the effects won’t be as dramatic as a stroker kit. However, it’s a fairly cheap alternative, but make sure to get it done from a reputed shop.

Forced induction is another alternative to stoker engines however this is an exercise that can easily get out of hand. The amount of money you might end up spending will depend on how sensible you are with the build.

It can cost as much as a stroker kit since there are things to keep in mind other than just bolting on a turbo or supercharger. Depending on the boost, you may have to strengthen the internals. Forged pistons, rods, crankshafts, performance intercoolers, manifolds, the list goes on and on.

If your goal is top-end power, de-stroking is a possible solution. It’s the opposite of stroking, i.e., you’re shortening the stroke length. You end up sacrificing low-end power for top-end punch.

It’s not so much how expensive it can be, but rather your requirement that should be considered. If your use case involves sitting at high revs, de-stroking is worth considering. Otherwise, for mixed-use, it’s not really worth the effort.

Should You Go Ahead With a Stroker Kit?

Now, coming to the main question. Are stroker kits even worth the effort? Well, it depends. For someone whose only commute is to and from work, they won’t provide much value and will likely be a waste of money.

But for people looking to get the most of their engine, this isn’t a bad idea, provided you have the budget to get it done. Stroker engines are by no means cheap, but the idea that they can unlock your engine’s untapped potential is worth the excitement.

What would you choose between forced induction and stroker kits? Let us know by leaving a comment below!