Turbocharging is absolutely the way to go when it comes to getting the most amount of power out of an engine. But with it comes turbo lag, which can be a real deal-breaker.

Although that’s only the case with large single turbos. If you want all the benefits that turbocharging has to offer minus the lag, you might want to consider sequential turbos.

There’s a reason why both the MK4 Supra and FD RX-7 had sequentially arranged twin turbos. And needless to say, those cars absolutely ruled the streets back in the 90s.

In this article, we’ll be going over what sequential turbos do, their merits, and why their popularity among automotive manufacturers has gone down over the years despite having several advantages.

Parallel vs Sequential Turbocharging

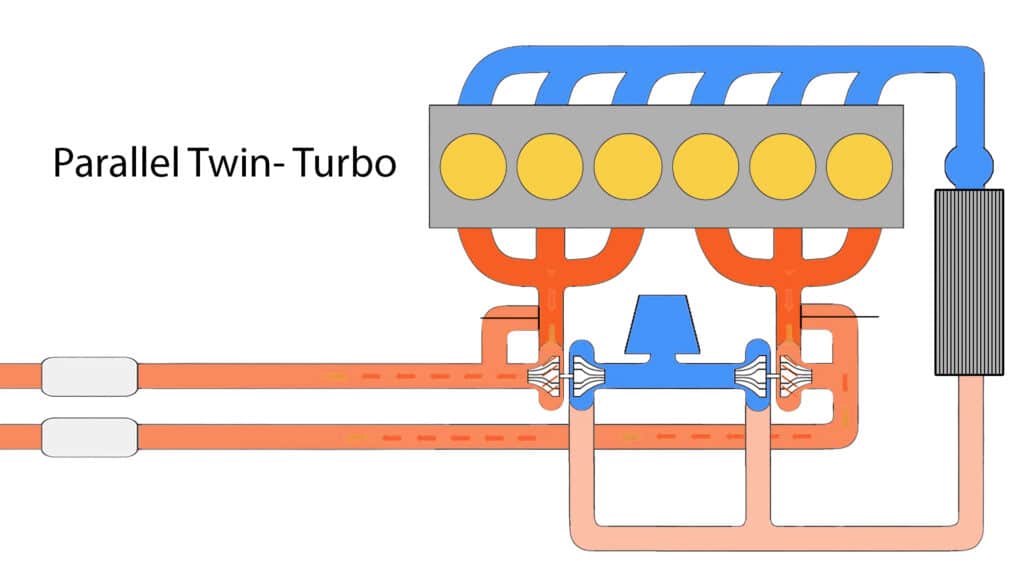

Before discussing how this style of turbocharging works, let’s discuss the difference between parallel and sequential turbocharging in short.

The twin-turbo or biturbo layouts were first introduced in a parallel arrangement, most commonly on V-layout engines. This meant each cylinder bank could have its own turbo as opposed to routing both cylinders into a single one.

Not to be confused with compound turbos, this setup involved the use of two small turbos as opposed to one large turbo because it takes less time for two small turbines to spool up than what it takes for one large turbine.

In other words, the force required to spool a large turbine is much greater than what’s required to spin a small one.

Effectively, parallel turbos achieve peak boost a lot quicker, owing to smaller turbine and compressor wheels that experience less inertia. Which means reduced lag times.

Even though parallel turbos noticeably improve response, the system still exhibits lag. That’s because the way it’s routed requires the air to travel a longer distance before it can enter the combustion chamber.

So even though the lag is reduced, the power band remains pretty much the same at low rpm. This is where sequential turbos come in, as they do things a bit differently.

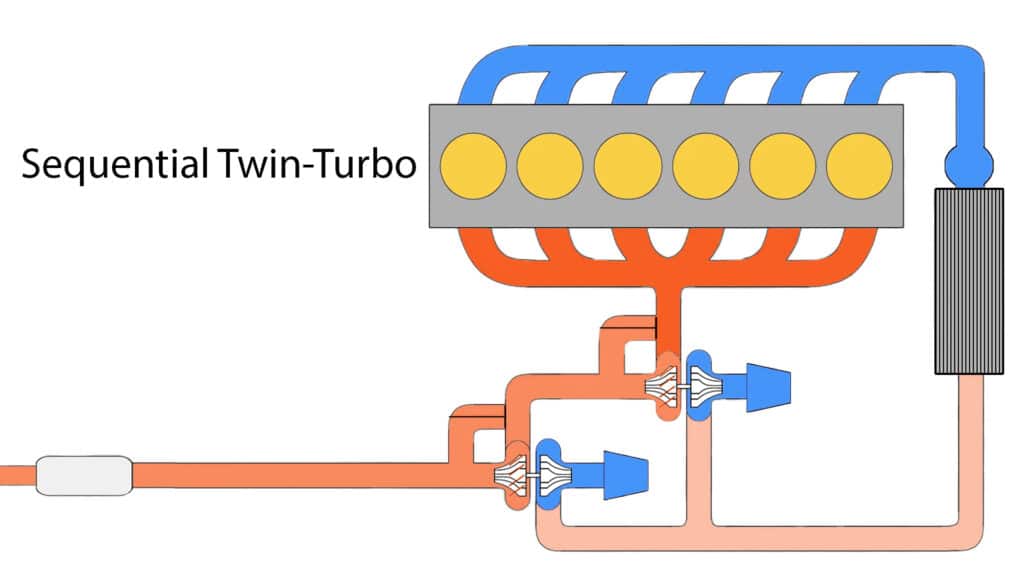

How Do Sequential Turbos Work?

Unlike parallel turbocharging which involves two small turbos working together the whole time, sequential turbocharging involves the use of two turbos — a small one and a large one.

The small turbo spools up quickly to give you a lag-free experience in the low rev range, after which the larger one takes over. This way you get the best of both worlds.

You get significantly reduced lag times and consistent boost across a wider rev range, ensuring the car doesn’t feel underpowered at low rpm.

Just know that some amount of lag will still be present, although not as much as what you’ll experience with parallel turbos.

An important difference between parallel and sequential arrangements is that turbos in the parallel setup are fed separately, whereas, sequential turbos share the same exhaust gases.

For instance, a parallel twin-turbo straight-six will have exhaust gases routed in a way that cylinders 1-3 will feed one turbo, while cylinders 4-6 feed the other.

But in a sequential setup, at low engine speeds, exhaust gases (from all the cylinders) are sent to the primary turbo and then to the larger turbo via a flap or valve.

It’s worth noting that both configurations use a turbo intercooler system, unless they are used for quick competition use, where lag can be the difference between winning or losing.

The switchover varies between manufacturers but usually happens around the 4000 rpm to 5000 rpm mark.

Why Aren’t Sequential Turbos Used Nowadays?

The simple answer is cost and complexity. Unlike parallel turbos, which are very common these days, sequential turbos require a myriad of pipes to keep both turbos connected to all cylinders.

This increases cost and brings in packaging constraints, two things that OEMs don’t really like.

The added weight and complexity could bring about reliability concerns as well.

A sequential setup might not necessarily have more problems than a parallel setup. However, it does have the potential to have more problems. The more complicated a system gets, the more opportunities for things to go wrong.

For instance, the sequential system’s flap or valve (vacuum-operated or otherwise) could easily be considered a vulnerable item. Should it fail, the whole setup is rendered useless.

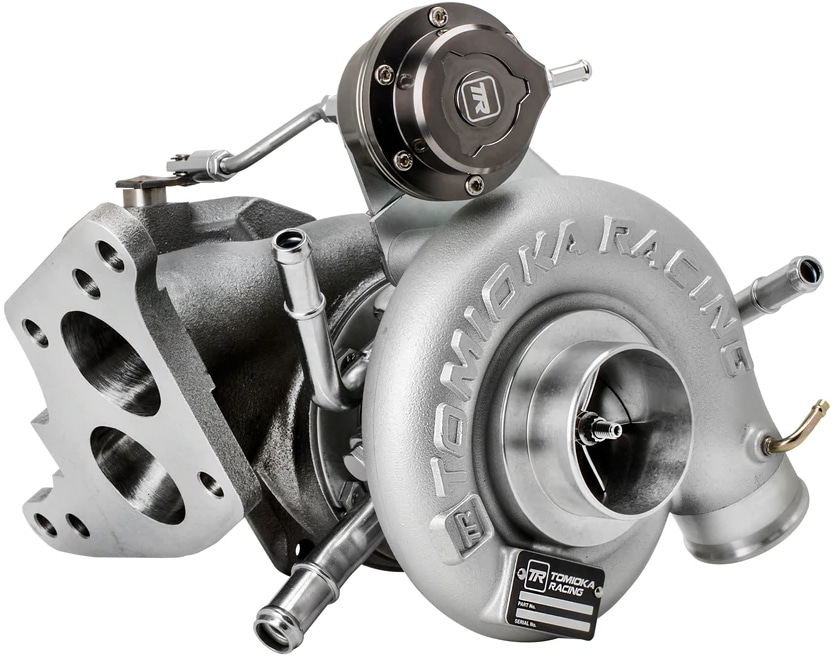

Another reason is the use of twin-scroll turbos that use separate channels to collect exhaust gases. It’s much less of a hassle to use these turbos in a parallel arrangement than employ a sequential setup.

Also, the aftermarket community largely prefers single turbos, owing to their simple, more reliable design and decent power gains.

Lastly, most mainstream OEMs (other than BMW) have switched to twin-turbo V-engines for 6 and 8-cylinder applications. And because there are two cylinder banks, designing a parallel setup is much simpler when cost and packaging are factored in.

Concluding Thoughts

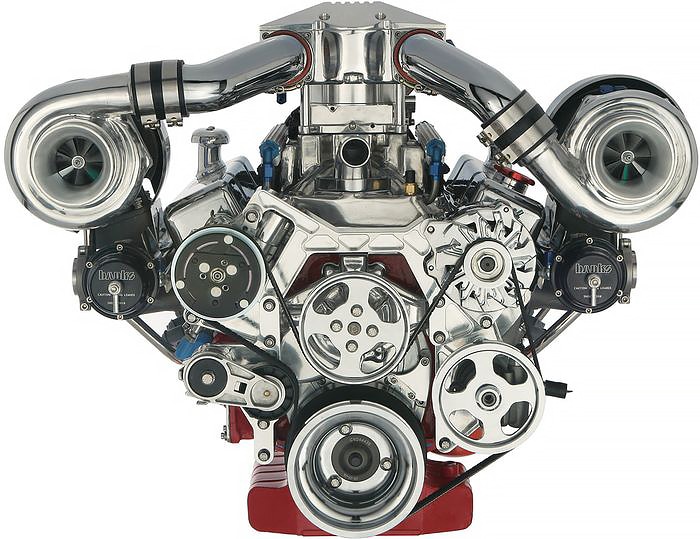

Even though sequential or compound turbos aren’t that common in 2022, many enthusiasts choose this layout for their FI build.

Some even choose to come up with their own rendition of this layout and opt for a full-custom build.

What’s your favorite forced induction layout? Which one would you side with in the supercharger vs turbo debate? Let us know by leaving a comment below!