The sound of a performance car is intrinsic to its character. It blends function with emotion to create a sensory experience that reflects its not just its engineering but also its character.

You don’t need a V12 to experience this. Even modest inline-4s can provide theater-worthy soundscapes with a little help from the automotive world’s favorite party trick: forced induction.

The characteristic turbo whistle and supercharger whine can easily rival the drama of much larger engines. Some prefer one over the other, but that’s subjective.

In this article, we’ll explore superchargers, understand why they sound the way they do, and learn how to make them louder.

How Superchargers Work

For anyone new to forced induction devices like superchargers and turbochargers, here’s a quick recap.

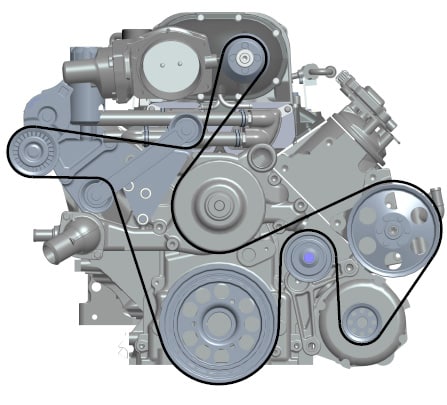

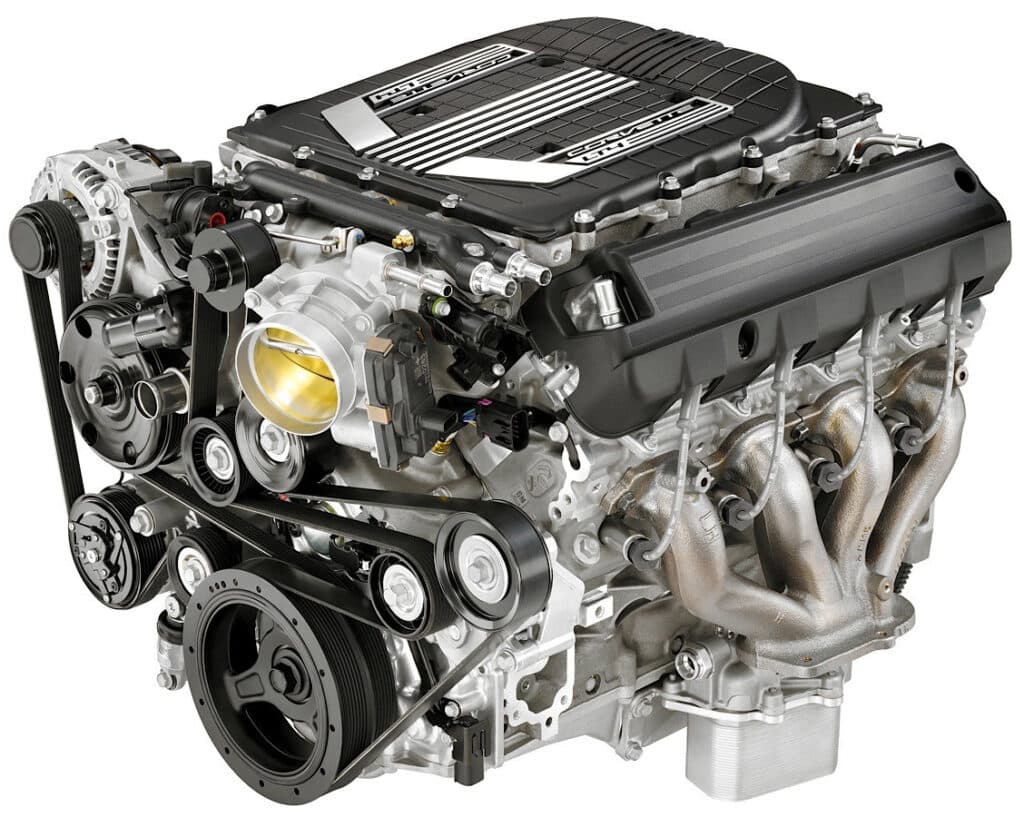

Unlike turbochargers that are driven by exhaust gases, superchargers rely on an air compressor driven directly by the engine’s crankshaft through a belt, chain, or gears.

Its goal is to compress the intake charge before it enters the engine. Compressed air allows for more oxygen to mix with fuel during combustion, resulting in a more powerful explosion.

Because it’s a direct drive system, it’s able to provide an instant boost without the lag that’s usually associated with turbochargers.

Factors Influencing Supercharger Whine

The primary source of the supercharger’s whine is its architecture and internal components, particularly the rotors.

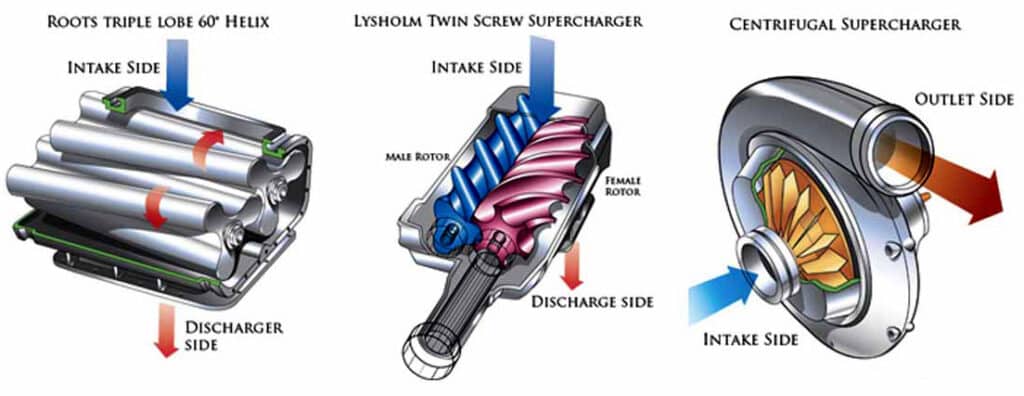

Most superchargers use either a roots-type or twin-screw design, consisting of interlocking lobes or screws that draw in air and compress it. These components rotate at high speeds, creating a symphony of mechanical noise.

As the rotors, or lobes, mesh together, they generate pressure waves and vibrations. These pressure waves manifest as sound, producing the distinct whine.

The supercharger’s design, rotational speed, and compressed air volume are a few variables that affect the whine’s frequency and intensity.

To visualize this, imagine two gears meshing together. As they interlock, they create pressure points that release small bursts of compressed air, akin to miniature sonic explosions.

These bursts of air release in quick succession, producing the high-pitched whine that we all know and love. Also, the supercharger’s rotational speed directly affects the whine’s pitch and intensity.

The pressure waves and vibrations become more frequent as the supercharger spins faster, resulting in a higher-pitched whine. Conversely, slowing down the supercharger decreases the frequency and intensity of the whine.

Here are some more factors that affect this phenomenon.

Compressor Design

The rotary design of a supercharger is a critical factor in determining its sound characteristics. Positive-displacement superchargers, like the Roots and twin-screw types, utilize tightly meshed rotors to compress air.

These designs inherently produce a prominent and high-pitched whine as the rotors rapidly force air into the engine. This sound is especially noticeable during acceleration when the supercharger is working hardest.

The twin-screw design typically offers a slightly sharper and more mechanical whine compared to the Roots, due to the precision machining of its interlocking rotors.

Centrifugal superchargers, by contrast, rely on an impeller that operates more like a high-speed turbine.

This design results in a smoother and less pronounced sound profile, often resembling the gradual spool-up of a turbocharger rather than the whine associated with Roots or twin-screw systems.

The difference stems from how air is compressed; centrifugal superchargers achieve compression through rapid spinning, while positive-displacement types move a fixed volume of air with each rotation.

Speed and Rotor Profile

The operational speed of a supercharger greatly influences its sound. As the rotors or impeller spin faster at a higher RPM, the pitch of the whine increases, becoming more pronounced.

This effect is particularly evident in setups with straight-cut gears, which amplify mechanical noise due to their design. High-speed operation not only accentuates the supercharger’s presence, but also adds to the overall auditory excitement.

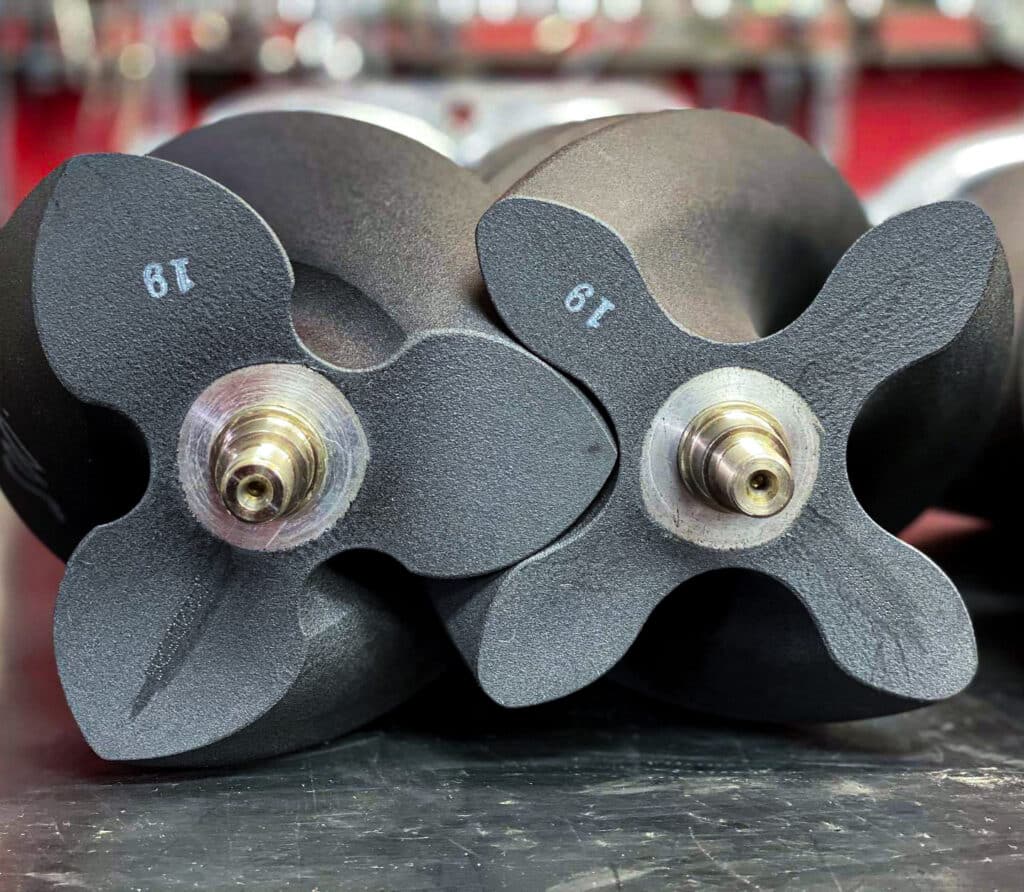

The rotor profile plays an equally significant role in shaping the sound. Straight-lobed rotors generally produce a more consistent but less dynamic tone, whereas twisted or helical rotor designs create a complex and distinctive whine.

Twisted rotors compress air more smoothly, often resulting in a sharper, more refined sound.

These variations are further influenced by the precision of machining, rotor clearance, and housing design, which together define the unique acoustic signature of each supercharger type.

Drive Mechanism

The method by which a supercharger is powered plays a significant role in the sounds it produces.

Belt-driven superchargers are the most common and are known for their characteristic noises, which arise from the interaction between the belt, pulleys, and gears.

As the supercharger spools up, variations in belt tension and load contribute to the distinctive whine, especially under acceleration. The belt’s material and alignment can also amplify these sounds.

These noises become especially noticeable during hard acceleration, where the belt system is under maximum strain, and sudden throttle changes, where rapid load shifts occur.

In addition to the belt itself, the type of gears—such as straight-cut or helical—within the drive mechanism influences sound production.

Straight-cut gears, commonly found in performance-focused setups, produce a louder and more mechanical whine compared to quieter helical gears. This interplay between the drive system components creates the supercharger’s unique auditory profile.

Acoustic Tuning

Many manufacturers now intentionally engineer their superchargers for a distinct acoustic signature, enhancing the auditory appeal of their products.

This tuning involves optimizing rotor shapes, gear profiles, and housing designs to emphasize or suppress specific frequencies.

The result is a “brand sound” that reflects the car’s character—aggressive and bold for performance-focused models or refined and subtle for luxury applications.

These deliberate design choices ensure the supercharger’s sound is as much a part of the driving experience as the performance it delivers.

Do All Superchargers Whine?

Not necessarily. It depends on many factors but mainly it comes down to how the compressor is designed. While the whine is a hallmark of many superchargers, not all produce the same sound. Some are much quieter than others.

For instance, roots-type and twin-screw superchargers are typically louder due to their rotor designs and straight-cut gears. On the contrary, centrifugal superchargers are generally quieter and sound more like a spooling turbo.

Many modern superchargers have design features meant to dampen the noise and be as quiet as possible.

If you want to supercharge your car but you don’t love the whine sound, research is key. Aftermarket kits can sound vastly different depending on what engine they’re installed on and how the intake system is designed.

Look for a model that suits your performance goals and sound preferences, whether that’s embracing the noise for its raw appeal or opting for a quieter setup. The latter is ideal if you’re building a sleeper car.

Making Your Supercharger Whine Louder

Enhancing the supercharger whine can be exciting for enthusiasts, but it requires thoughtful consideration of cost, practicality, and potential impacts on performance.

Noise regulations and the risk of harming engine reliability should also be carefully weighed before making modifications. If you’re determined to amplify that distinct sound, here are a few options:

- Install a Twin-Screw Supercharger: Known for their signature high-pitched whine, twin-screw superchargers provide an unmistakable auditory experience, albeit at a higher cost.

- Modify the Intake System: Adjusting the intake setup to reduce restrictions and increase airflow can amplify the whine. Open air filters or modified intakes are popular options.

- Change Pulley Size: A smaller pulley increases the supercharger’s spin rate, boosting both performance and the characteristic whine. Just be sure to account for the added strain on the system.

With careful planning and the right modifications, you can enjoy a louder, more aggressive supercharger whine without compromising engine performance.

What’s your take on superchargers vs turbos? Let us know your opinion by leaving a comment below.