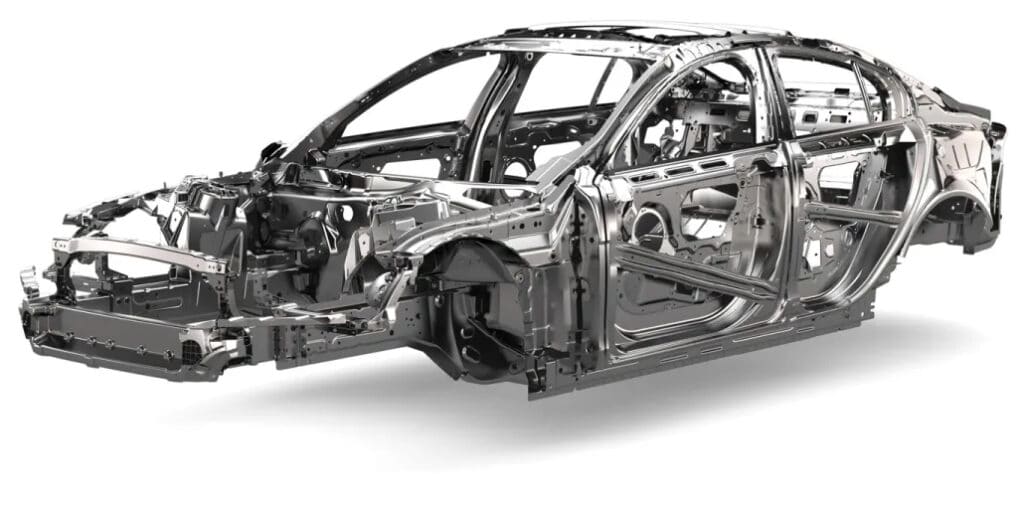

The chassis is to the car what the skeleton is to the human body — a load-bearing frame that holds everything together.

Your car’s chassis design has a huge impact on the way it drives, the way it turns, and pretty much everything it does when in motion.

You must’ve heard of words like monocoque, unibody, and space frame thrown around in the world of automotive design.

Each of these refers to structural systems that automotive chassis are based on. They all do the same thing, but they do it a lot differently.

In this article, we’ll explore the space frame structure, discuss what it is, how it works, and how it compares to other chassis types.

Understanding Space Frame Structures

The space frame structure is not exclusive to automobiles. It’s widely applied in architecture and structural engineering.

It’s one of those things that you probably see and reap the benefits of on a daily basis but never notice. Once you know what they are, you’ll see them everywhere.

History

Interestingly, the same person who invented the telephone contributed to the development of space frames as we know them today.

Back in 1907, Alexander Graham Bell was obsessed with the idea of making kites that could lift a person off the ground.

His experiments with tetrahedral trusses inadvertently led to their initiation in the world of architecture, thanks to further development by Max Mengeringhausen for his MERO space grid system.

Around that time, the automotive industry also got its first taste of space frames when William B. Stout unveiled his Stout Scarab, not to mention Buckminster Fuller’s Dymaxion Car.

How They Work

Space frames (also called 3D truss) are structures made up of interlocking struts and braces, organized in a geometric pattern that resembles a series of tetrahedrons — pyramid-like shapes with 4 triangles.

The most common use for space frames in architecture is to span large areas with very little interior support. In the automotive world, space frames are used to design ultra-rigid, lightweight chassis for high-performance vehicles.

A large proportion of the space frame’s strength can be attributed to the triangle’s inherent rigidity. There’s a reason why the shape is called “an engineer’s best friend”.

In contrast to plain frame structures which are subjected to complex forces such as bending, shear, and torsion; space frames facilitate rigidity only through tension and compression.

Put simply, they do an excellent job at distributing forces throughout the structure, making them strong and lightweight.

Why Space Frames Chassis Make Sense

If we were to choose a favorite among monocoques, semi-monocoques, space frames, and ladder chassis, we’d be stumped.

They’re all made for different purposes and work wonderfully within their specific applications.

For instance, monocoques are ideal for mass production, ladder chassis work beautifully for SUVs and pick-up trucks, but space frame chassis top the charts when it comes to rigidity/weight ratio.

The main challenge for any automotive structure is torsional rigidity, which refers to the twisting force that the car is subjected to when banking into corners or driving over uneven terrain.

Optimal torsional rigidity improves the ride quality by allowing the suspension to work more efficiently, but the lack thereof negatively affects lateral weight transfer.

Check out our guide to suspension geometry and roll center to know more about why weight transfer is a big deal.

No matter how strong a chassis is and what materials are used to build it, what ultimately dictates its structural rigidity is the geometry.

This becomes clearer when you consider how there’s a day and night difference between strength and rigidity.

As we mentioned earlier, the rigidity of space frames can be attributed to their tetrahedral structure which carries all the load in tension or compression, not in bending.

If the load is carried in bending, then it’s not a true space frame.

Space frame cars are unparalleled when it comes to torsional rigidity. The body panels have no structural function, the frames are unbelievably lightweight, and they make for an excellent kit-car solution.

Concluding Thoughts

Despite all the advantages, few production cars use this frame design, owing to the challenges involved in manufacturing space frames on a large scale.

Cars like the 1959 Maserati Tipo 61 Birdcage, and the Porsche Type 360 Cisitalia were among the first space frame race cars ever made. Almost all Ferraris before the 360M use this frame design.

The Lamborghini Diablo and Countach; Jaguar XJ220, and the TVR Tuscan are a few more examples.

What’s your favorite space frame car? Let us know by leaving a comment below!

Feature Image: Engineered to Slide, Space Frame Hilux