As a simple enough bolt-on addition, turbochargers have contributed a lot to the development of motoring. Using a turbo meant extracting more power from an existing setup, all with little to no loss in efficiency.

From hearing the sweet wastegate whistle to producing monstrous output, a turbocharger has the power to make any boring car or truck feel cool, too. But the real fun begins when two are involved.

If you want to learn more about compound turbo setups, read on. We’ll run you through what they are, how they differ from other twin-systems, and their biggest advantages.

What Is a Compound Turbo?

Many people confuse this system to yet another variation of twin-turbocharging. While it’s true to a small extent, compound turbos function very differently to twin turbos, be it sequential or parallel arrangements.

Sequential turbocharging uses turbos of different sizes operating at separate rpm bands, whereas in parallel turbocharging, two turbos of the same size act as one large unit.

On the other hand, compound systems features two turbos working in series. That is, one turbo feeds another turbo.

But Why Employ Staged Turbos?

Well, sequential and parallel turbocharging are usually found in gasoline cars, where there are revs to play with.

What if you want to generate the same power in a diesel engine? Well, it can’t rev as high as a gas powered car, so the only way is to multiply the boost pressure at delivery using compound turbos.

To learn more, let’s get a better understanding of what sequential and parallel forced induction systems are, and how they function.

How Are They Different From Parallel and Sequential Systems?

Both systems feature two turbochargers. Sequential turbos are generally two different sizes whereas parallel systems usually feature identical turbos.

While parallel turbos help to reduce lag and improve response, the car still exhibits lag at the lower end.

The purpose of sequential turbocharging is to keep boost across a wider rev band, ensuring the car doesn’t feel underpowered at low engine speeds.

Unlike parallel turbochargers, sequential turbos utilize a smaller turbo that functions at lower revs, and a bigger turbo to take care of top end power.

So How Do Compound Turbochargers Work?

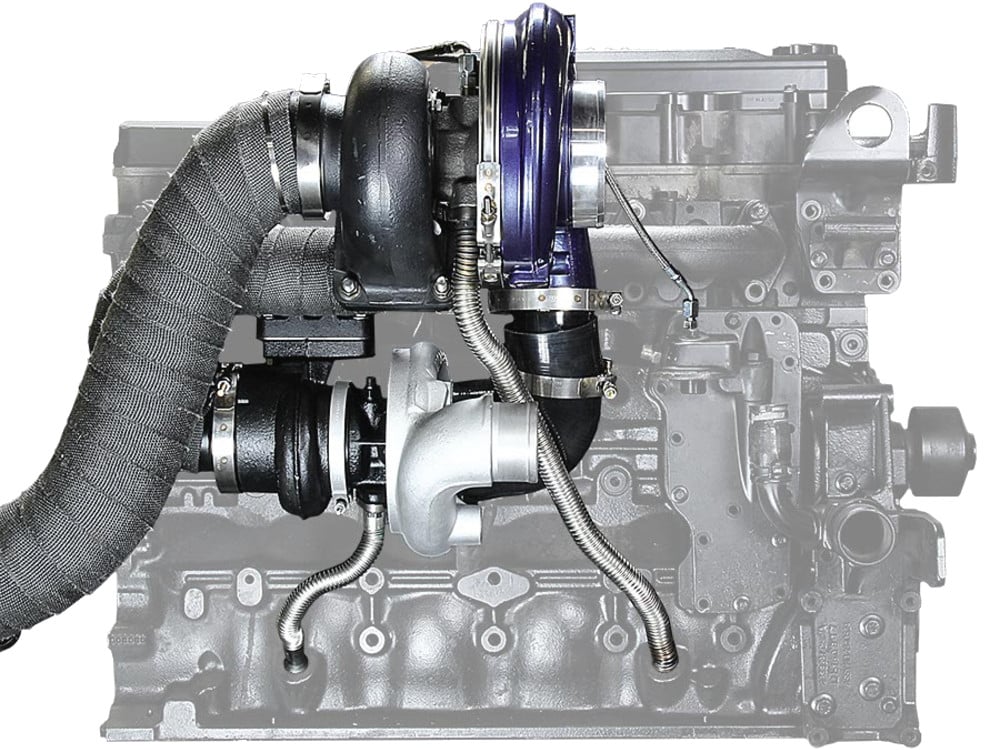

Simply put, they—much like sequential systems—have two turbochargers of varying sizes, which are arranged in a series layout. Unlike sequential turbochargers, compound turbos are ‘sort of’ symbiotic in their relationship.

Best explained by Bruce Smith at Motor Trend, a compound setup’s intake side has the larger secondary atmospheric turbo sucking in fresh air, compressing it, and then sending it directly into the smaller, primary high-pressure turbo, which is mounted on the exhaust manifold.

Simultaneously, the smaller high-pressure turbo feeds exhaust directly to the larger atmospheric turbo, helping it spool up.

In terms of working—on the exhaust side—the primary turbo receives the exhaust flow first. Given that it’s small and lightweight, it can easily take care of the engine’s low rpm boost requirements.

The real magic of compounding starts when the high-pressure primary turbo starts reaching its maximum rpm.

Technically, the primary turbo can longer produce boost since it’s already maxed out, so now, the secondary turbo kicks in.

Valves in the primary turbo open, bypassing exhaust gases directly to the secondary atmospheric turbo so that the engine still has boost even in the mid-to-high rev ranges.

But isn’t that sequential turbocharging? In a way, yes. But what really separates the two systems is what happens after the larger secondary turbo kicks in. And yes, it’s normal to be confused at this point.

Why People Get Them Confused With Other Systems

You could argue that compound turbocharging is another fancy word for twin turbocharging.

The reality is that all three turbo systems are unique in their design, installation, piping, and other engineering tolerances.

The biggest difference between compound and twin-turbocharging is that the former is a single-stage system, whereas the latter is considered two-stage.

What people confuse about compounds is the intake side, where the process is opposite to the exhaust side.

In simple terms, when the secondary “low pressure” turbo kicks in, air is sucked from the atmosphere (hence atmospheric turbo), compressed to 2x or 2.5x (depending on the setup) and fed into the primary high-pressure turbo, which compresses it further.

In a sequential turbocharging system, it’s usually either the smaller turbo or the bigger turbo that takes care of building boost. The switchover varies between manufacturers but usually happens around the 4,000-5,000 rpm mark.

Unlike a compound arrangement, at no point are the two turbos in a sequential arrangement helping each other multiply the boost pressure. Looking at the schematics of a compound turbo system should bring more clarity.

Another example to help you understand this system is by thinking of batteries connected in series and parallel:

- A parallel battery system provides twice the current versus a serially arranged system (increased flow rate).

- When batteries are in series, they make twice the voltage (more pressure).

Think of situation ‘1’ as parallel twin-turbocharging and situation ‘2’ as compound turbocharging.

Essentially, both systems are devised to increase boost. However, it’s where they are applied that makes a difference.

As mentioned earlier, diesel engines have less rpms than gasoline engines to create boost. So, for a diesel to make the same power as a gasoline motor, it requires using a compound arrangement.

That’s not to say you can’t run a compound system on a gas fueled engine, it’s just less common. There are some insane Toyota 1JZ and 2JZ builds with huge horsepower thanks to this configuration, as well as this incredible Nissan SR20 engine built by Mazworx.

Compounding Advantages

The benefits are plenty. You get good low-end torque, punchy mid-range, and exciting top-end performance. Additionally, you have accessible power throughout the rev range, as well as better drivability at any given rpm.

On top of that, the engine runs more efficiently. This is because the “high-pressure” small turbo is utilized to get things started at lower rpm, while the larger atmospheric “low-pressure” turbo is given the baton at higher speed.

You could still opt for a small or large single turbo for boost requirements, and you will see noticeable improvements. However, you’ll inevitably be “stuck” in a specific power band.

Compound turbos eliminate this need to sit in a particular rev range.

Another advantage of compounds over single systems is that they keep exhaust and boost pressures nearly equal.

The Exhaust Gas Temperature (EGT) is far cooler when running compounds because the charge air is denser, cooler, and of greater volume than what you get from a single turbo.

What About Reliability?

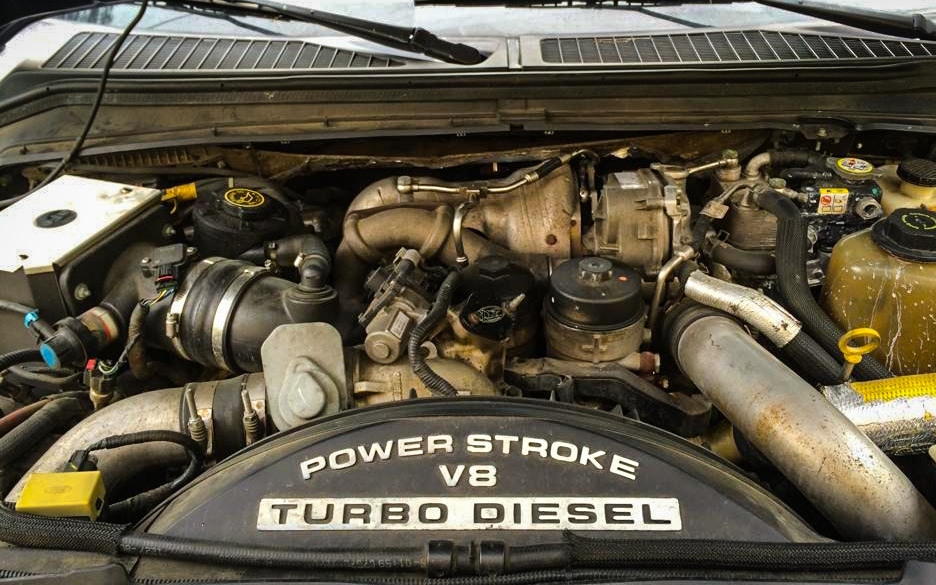

Some OEM engines like Ford’s 6.4L Power Stroke came with a compound arrangement from the factory.

Even if you have a single turbo OEM setup, there is no harm in combining the stock system to devise a compound unit.

However, most OEM turbos in light-duty diesel trucks are smaller to aid in better throttle response. You can combine the OEM turbo’s quicker response with an aftermarket low-pressure turbo’s top-end punch to run a compound setup.

Several owners are already fond of the idea. But it’s important that set your system up based on your requirements.

Any diesel performance expert will tell you that compound turbos are arranged differently for different purposes. Someone who frequently tows a lot will run a different system versus a street or race truck.

As for reliability, this system will not make your truck any less reliable. What most people end up doing, however, is exploiting the added potential.

While there is an increase in response and efficiency (ranging from 18-23%, depending on the build), that doesn’t mean you need to be on the accelerator pedal all of the time.

Also, since there is more headroom available, many go ahead with increasing the power output. If you set it up sensibly, reliability won’t be an issue.

A more obvious way of explaining this is—400-500 horsepower is very different from 700-800 horsepower.

Not only do those extra horses increase the load and wear on parts, but it significantly drops drivetrain longevity. Bear in mind that the increased wear is not necessarily due to running compounds.

It’s down to taking the opportunity to add more power. At the end of the day, it all boils down to need.

If you’re a frequent visitor of the drag strip, 700 horsepower is justifiable. However, you can’t expect reliability to be the same as a simple street engine running 500 horsepower.

How Much Does a Compound Setup Cost?

If you’re wondering about pricing, the total installation cost depends on the shop, truck, labor, and a decent tune. Expect your build to cost upwards of $2,500.

For example, Duramax systems cost in the low $4,000 range, while 2011 and later Power Stroke systems are in the $5,000 ballpark.

Early Cummins 5.9 and 6.7 compound turbo kits are cheaper, available under $2,000. Second-gen Cummins 5.9 kits cost around $2,500, while the third-gen 5.9 will cost almost $3,000. Later Cummins systems generally run up to $3,500.

Some kits only include a new turbo manifold, cold air intake, piping and oil lines, but don’t come with an additional turbo. This is something you’ll really want to check as you’ll probably need to spend $750 or more for a turbine.

Most kits will use your factory intercooler (assuming you have one), but if you’re going for a performance kit, an aftermarket turbo intercooler might be included as well.

If budget is a concern, the best place to save some cash is on doing the work. If you like getting your hands dirty, you can save around $1,500 in labor costs by installing it yourself.

So, do you think these systems are underrated? Are you planning to install one in your car?

If you enjoyed reading this post, please share it on Facebook, Reddit, or your favorite online community. We appreciate your support!