Exhaust systems are extremely complicated. What looks like just a bunch of metal pipes merged together is actually an engineering masterpiece — every fold, bend, and pipe diameter is carefully selected to achieve a specific effect.

This “effect” has a lot to do with balancing out the three most important characteristics of the exhaust system:

- Exhaust Scavenging,

- Backpressure, and

- Exhaust Velocity.

This is true for both OEM and aftermarket exhaust systems, with the exception that OEM exhaust systems are more geared towards compliance with emissions standards over outright performance.

Before you upgrade your exhaust system, it’ll help to familiarize yourself with concepts such as scavenging and backpressure.

We’ve touched on these concepts in one of our articles that explains how exhaust systems work and what components are involved.

In this article, we’ll briefly discuss the scavenging effect — what it is, what it does, and why you should understand it.

What Is Exhaust Scavenging?

Put simply, scavenging refers to the process of replacing spent gases in the engine cylinder with a fresh charge of air and fuel.

Your engine is basically a large air pump that makes power by rotating pistons through a crankshaft, powered by multiple explosions of air and fuel sprayed in a fine mist.

Every modern four-stroke engine follows the same cycle:

- Intake: Air-fuel mixture enters the combustion chamber.

- Compression: Piston travels up to top dead center and compresses the air-fuel mixture.

- Combustion: The spark plug ignites the air fuel mixture, and the piston gets pushed to bottom dead center.

- Exhaust: Piston travels back up to top dead center, but this time it pushes the spent exhaust fumes out through the exhaust valve.

The whole point of the exhaust stroke is to expel the spent gases that remain in the engine cylinder (better known as the combustion chamber) after the combustion cycle is completed.

When the spent gases are evacuated, it frees up the much-needed space for the next combustion cycle. But have you ever wondered how exactly the exhaust system draws the spent gases out of the engine cylinder?

Sure, the piston does some of the work by pushing the gases out when the exhaust valve is open, but there’s a lot more at play — enter the scavenging effect.

How Does Exhaust Scavenging Technology Work?

There are two main forces involved in scavenging:

- The piston pushes out exhaust fumes while travelling back up to top dead center, and

- The pressure differential between the combustion chamber and the exhaust manifold causes the exhaust gases to get pulled out.

Allow us to explain — the pressure within the combustion chamber is 6 to 7 times higher than atmospheric pressure, and the pressure outside the combustion chamber (in the exhaust manifold) is equal to atmospheric pressure.

Naturally, the exhaust gases are going to want to move towards the low-pressure area, that is, out of the engine cylinder, and into the exhaust manifold. This happens because gases tend to travel from high pressure to low pressure — that’s why wind exists.

And it is this pressure differential that causes exhaust gases to leave in the first place.

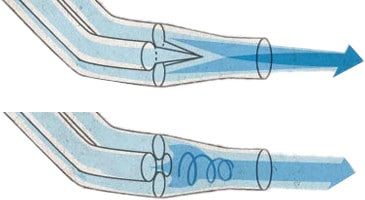

Now, remember that exhaust gases travel in pulses; not in a stream. When these gases leave the engine, a negative pressure wave follows each exhaust pulse sent out by individual cylinders.

It is this negative pressure wave that helps to draw the next exhaust pulse behind it (like a vacuum), and the cycle keeps going. This is referred to as scavenging.

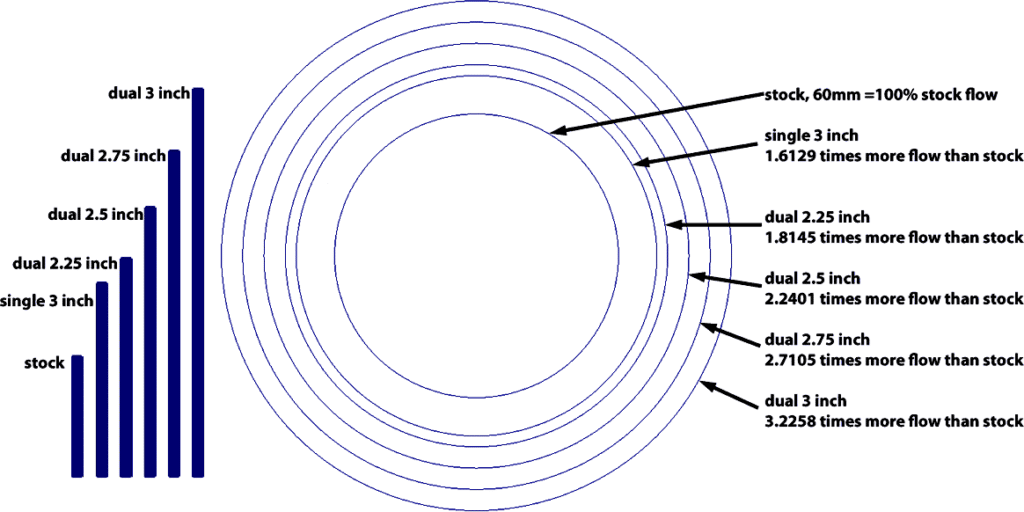

The faster these exhaust fumes leave the engine (exhaust velocity), the more efficient the scavenging process will be. That’s why aftermarket exhaust system manufacturers design their exhaust systems in a way that maximizes the scavenging effect.

Final Thoughts

Exhaust systems are dynamic in nature and many variables associated with them keep changing. For instance:

- Combustion chamber volume keeps changing as the piston keeps moving.

- Temperature fluctuations.

- Airflow rate fluctuations.

- Exhaust velocity as a result of constantly shifting rpm.

That’s why there’s no “one true exhaust setting” that works for all cars — especially for those that aren’t naturally aspirated. Exhaust scavenging works differently for forced induction or turbo applications.

All cars, engines, and exhaust systems are different. Not just that, the driver’s preferences and use cases matter too.

Some want the best scavenging and backpressure characteristics early in the rev range while some prefer it at the top end. All of this can be precisely configured with the help of aftermarket exhaust systems, custom exhaust components, intake system modifications, adjusting valve timing, and ECU tuning.

Understanding these things will put you in a better position to make decisions about modifying your exhaust system or anything else that has to do with how your car breathes. While some people simply want to make their exhaust loud, if you want better performance, you need to pay closer attention to the changes you’re making.

To recap, the two main goals of scavenging are:

- Evacuating the exhaust chamber as quickly and effectively as possible.

- Allowing for there to be less pressure in the combustion chamber for the piston to fight against. This improves the volumetric efficiency.

- Aiding additional air intake and exhaust flow during valve overlap.

And that concludes our quick guide to exhaust scavenging. What do you think about aftermarket exhaust systems? Are they worth it? Let us know by leaving a comment below!