There’s a lot of misinformation out there about automotive exhaust systems and the concepts associated with them. Exhaust back pressure is one such concept that’s widely misunderstood. This is mostly a consequence of misinterpreted test results and good ol’ hearsay.

Back pressure is actually quite simple — as the name suggests, it is the pressure that pushes back on your exhaust system against the direction of flow. Even though it isn’t desirable, back pressure plays a vital role in the functioning of your exhaust system as it dictates a lot of the design characteristics. More on that later.

When exhaust scavenging, back pressure, velocity, piping diameter, valve timing, and overlap are all optimally balanced, what you end up with is an ideal exhaust system setup. However, this is subject to many variables. We’ve explained this in detail towards the end of our exhaust scavenging guide.

Remember that most of the rules change when it comes to cars fitted with an aftermarket turbocharger; or even OEM turbo cars for that matter.

In this article, we’ll explain what back pressure is, and shed some light on the popular myth about back pressure being good for your engine.

What Is Exhaust Back Pressure?

Back pressure refers to a pressure buildup in the exhaust system that interferes with the outward flow of spent gases. It is the pressure opposing the desired exhaust flow — think of it as the exact opposite effect of scavenging.

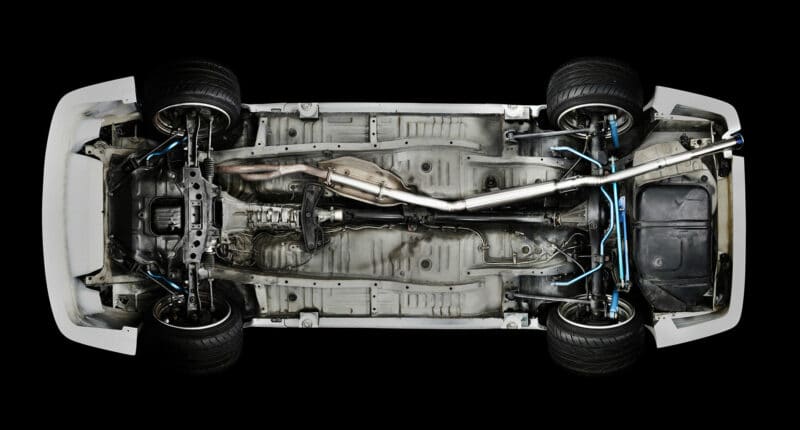

The entire exhaust system is basically one large flow restriction that we can’t do without for multiple reasons:

- The exhaust pipes need to redirect the fumes away from passengers.

- The catalytic converter needs to clean up spent gases to meet emissions regulations.

- The muffler softens the exhaust note to meet noise regulations.

The list goes on. Each of these components adds some amount of restriction. And with restrictions comes back pressure — this is never desirable.

To understand why this isn’t desirable, you need to know how scavenging works because both concepts are extremely intertwined. Let’s recap real quick.

Exhaust scavenging is the process by which spent gases are drawn out of the combustion chamber and expelled into the exhaust system. This happens because there’s a pressure differential between the part inside the engine cylinder (combustion chamber) and the part outside the engine cylinder (exhaust manifold).

Gases always travel from areas of high pressure to low pressure. The pressure within the combustion chamber is 6 to 7 times higher than what’s in the exhaust system. That’s why the spent gases gush out at the moment when the exhaust valve is opened.

Spent gases exit through multiple cylinders at high speed and pressure, in the form of pulses. Each time these pulses merge at different points in the exhaust system, a trailing negative pressure wave is created — especially right after the exhaust valve shuts.

This negative pressure wave travels back to the next exhaust valve and helps to evacuate the gases even quicker (because of the same reason; gases like moving towards low pressure). If there’s valve overlap, the scavenging effect can also help draw in more air into the engine simultaneously.

Engineers strive to tune exhaust systems to time everything perfectly and allow the exhaust valves to open right at the point when the negative pressure wave arrives.

Back pressure hinders this process — it is counterproductive.

Is Back Pressure Good or Bad?

It’s clear that exhaust gases like to flow from high pressure to low pressure. The higher the pressure differential, the easier it is for the exhaust fumes to flow out of the cylinder. This means you want a maximum pressure differential to achieve high volumetric efficiency.

Adding back pressure is only going to lower the pressure differential, making it harder for exhaust gases to escape (poor scavenging). This creates two problems:

- Volumetric efficiency drops, that is, exhaust gases don’t get vented effectively, which means that an insufficient amount of air and fuel gets drawn into the cylinder (there’s only so much space to work with). This reduces power output.

- Because some of the exhaust gases fail to escape, the next combustion cycle gets affected negatively.

With that in mind, back pressure is clearly a bad thing. And guess what causes back pressure — restrictions.

The more restrictive your exhaust system is, the more bends it has, the more back pressure you’re going to get. The reason why aftermarket exhausts are desirable is that they have fewer restrictions compared to your stock setup.

If you’ve tried researching this topic in the past, you’ve probably heard that some amount of back pressure is actually good for your engine — this is a logical fallacy.

Do All Exhausts Need Back Pressure?

You don’t need back pressure. More accurately, back pressure is an inevitable consequence of trying to increase performance. No matter what you do, your exhaust system will naturally generate some amount of back pressure.

This is mainly because exhausts are transient state systems, not steady-state, that is, they’re dynamic. As the rpm and exhaust velocity change, what the engine needs in terms of exhaust design also changes.

But you can’t really change your tubing length on the fly; you’re pretty much stuck with what you have installed.

That’s why it’s always a trade-off — if a certain tubing length gives you peak performance in a certain rpm range, it’ll give you worse performance in other parts of the rev range.

It’s up to you to decide what part of your rpm range you want the peak performance to be in. That way you get better scavenging where you want it, and worse scavenging where you don’t care. Either way, you’re going to end up with back pressure somewhere — unless you’re running unequal length exhaust runners, but more on that in another article.

Negative Results From Less Back Pressure

All of this considered, there are some people who have experienced poor drivability as a result of removing back pressure — perhaps by removing restrictions such as the catalytic converter or the resonator.

While they’re not wrong, their assumption that “removing back pressure” was the culprit behind poor drivability is incorrect. When you remove restrictions from your exhaust system without tuning the ECU, or without compensating for the new exhaust flow characteristics, it creates problems.

So long as you compensate for the changes you’re making in your exhaust system, removing or reducing back pressure will always be a good thing. Take a look at the exhaust headers on drag cars for instance.

This myth has more to do with exhaust velocity than back pressure. Someone probably did a bunch of experiments with variable pipe diameters, got better results with narrower pipes, and assumed that it was the back pressure that’s helping performance. It must’ve been faster exhaust velocity and better scavenging that was doing the trick.

Few people know how the exhaust back pressure myth came about and we’ve heard a few different theories. Where do you think the myth came from? Let us know in the comments below!

6 comments

My brother is a pretty smart guy, engineer and all. Something he told me when I was just getting to the age of mechanical understanding is that insufficient back pressure can cause burnt exhaust valves. Though this may be over some time, still if your talking economy, prematurely burnt exhaust valves is not good. However if your talking horsepower for fun or sport you are usually planning on spending an engine relatively quickly any way. So I guess it’s just a matter of what you are really trying to achieve with your project. Your take?

It is to my understanding that as long as you’re getting the exhaust gasses flowing away from the head, and away from the exhaust valves, there will be no issues. Header tube length plays a big part in that. If the header tubes are too short, or if you run an engine without headers or an exhaust manifold at all, and you let the exhaust gasses come straight out of the exhaust valves to atmosphere, that’s where you will run into issues with the exhaust valves getting too hot. Scavenging with longer header tubes will pull that heat away from the valves.

“Something he told me when I was just getting to the age of mechanical understanding is that insufficient back pressure can cause burnt exhaust valves”

For an engineer, it’s a very strange thing to say. Thinking about it, if less backpressure means more air being moved along, how would valves get burnt? Just seems very odd at first glance.

From my own personal experience it has changed what backpressure is forever. As much emphasis should be placed on not enough.

I went stage 2 from stage on introducing a new hfc before the actual tune and the performance at high throttle iff the line was noticeable.

Ffwd to a rusted hole in the resonator and the performance loss was massive, again, off the line and high revs.

So here I am booking an sppointment with a custom exhaust shop that can handle stainless steel piping which is a rarity and I am in a major city.

Not enough knowledge is known besides mear bro science about exhaust pressure. Too much us definitely not good if your tune isn’t mapped for it.

Logic would say, if someone has removed backpressure but not adjusted any timings associated with the exhaust system, the liklihood is that they have inadvertently arranged that the valve opens at higher than ideal pressure which will kill scavenging and thereby reduce the effectiveness of the engine and grant an effective loss of power.

Still doesn’t explain all the boy racer types that would floor their engines only for me to pass them in a stock, NA 1.9L Diesel Berlingo that lost speed if the rubber mat got stuck under the accelerator…

“Take a look at the exhaust headers on drag cars for instance — they point straight to the sky. No back pressure whatsoever.”

Why does everyone forget atmospheric pressure? 14.7 psi @ sea level. “No back pressure whatsoever” is just flat out wrong.